Abstract

Carbon nanotubes (CNTs) are promising nanomaterials for the preparation of nanohybrids and nanocomposites with polymers. In the preparation processes, surface modification and functionalization of CNTs have key roles to enhance the compatibility in organic solvents or water for solution processing routes; furthermore, they improve the interfacial compatibility between CNTs and the polymer matrix to avoid CNT aggregation in CNT/polymer nanocomposites. Hence, we have developed three approaches for directly reacting chemical agents and polymer chains with multi-walled CNTs (MWCNTs). The methods are: (i) sequential atom transfer radical addition to MWCNTs, which conveniently builds up polymer architectures on MWCNT surfaces; (ii) ozone-mediated addition reaction, which effectively chemically bonds non-reactive polymer chains to MWCNTs; and (iii) Diels–Alder reaction-mediated MWCNT functionalization, which achieves thermally reversible functionalization/de-functionalization of MWCNTs. On the basis of the new reaction routes, the scopes of nanohybrids and nanocomposites of MWCNT/polymers and their properties and functions have been significantly enhanced and extended. Some examples are discussed in this review.

Similar content being viewed by others

Introduction

Conventional composites comprised of inorganic reinforcements and an organic polymer matrix combine the attractive properties of these two components. When the sizes of the inorganic fillers are reduced to the nanoscale and the fillers are homogeneously dispersed in the polymer matrix on the nanosized or molecular levels, the corresponding composites are called nanocomposites and have shown useful and distinct properties, such as mechanical strength, toughness, dimensional stability, heat resistance, flame retardancy and barrier properties, compared with the conventional composites.1, 2, 3, 4, 5, 6, 7 Consequently, many types of nanosized fillers, including zero-dimensional nanoparticles, one-dimensional nanotubes/nanowires, and two-dimensional nanosheets (for example, clay and graphene), have been studied for the formation of the corresponding polymer-based nanocomposites. Among the nanosized fillers for nanocomposites, carbon nanotubes (CNTs) have attracted significant research attention based on their excellent mechanical and electrical properties and the morphological advantage of high aspect ratios.8, 9, 10, 11, 12, 13, 14 Moreover, large-scale production of CNTs has been successfully performed to produce commercially available products with reasonable prices.

Because the inorganic nanofillers are expected to homogeneously disperse in the polymer matrix on the nanoscale, the most critical issue for nanocomposite preparation is to avoid aggregation of the nanofillers in the fabrication process. As a result, organo-modification of the inorganic nanofillers to improve their interfacial compatibility with the polymeric matrix is the first and key step. CNTs are allotropes of carbon that are entirely composed of sp2 bonds. Their chemical structure lacks oxygen- and nitrogen-containing polar groups, resulting in the high hydrophobicity of CNTs. Hence, CNTs naturally have less interaction with polar solvents and polymeric materials and tend to aggregate owing to their own strong π–π interaction. Therefore, organo-modification is critical and necessary for CNTs in the preparation of polymer/CNT nanocomposites.

Polar and organic moieties have been incorporated into CNT outer surfaces physically and chemically. Polynuclear aromatic compounds15, 16, 17 and conjugate polymers18, 19, 20 have been widely utilized as the physical modifiers for CNTs based on their strong π–π interaction with CNTs. The physical modification of CNTs is reversible and does not alter the conjugate structure of CNT surfaces. Nevertheless, the method has less molecular design flexibility compared with the chemical approaches. The conventional routes to chemically modify CNTs start with the oxidation of CNT bundles by strong acid (nitric acid and sulfonic acid) treatment.21, 22, 23 Oxidation of the CNT bundles generates carbonyl acid groups on the CNT surfaces, which could act as versatile chemical groups for further CNT functionalization, such as esterification, amidation and nucleophilic addition to epoxide groups. Nevertheless, acid oxidation cuts the CNT bundles to decrease their aspect ratio and eliminate the caps of CNTs to transform the resulting CNTs into open tubes.24, 25 On the other hand, chemical modification methods involving reactions at the unsaturated C=C groups of CNT surfaces are attractive and have been widely studied (Figure 1). Many reagents have been applied to CNT surface modification for the design and preparation of functional CNTs and the corresponding nanocomposites.26, 27, 28 Nevertheless, there are problems to be solved, including (i) an easy and convenient approach to perform controlled polymerization on CNTs and to prepare well-designed CNT-polymer nanohybrid materials; (ii) a general method to chemically bond different types of polymer chains, especially the commercially available engineering plastics, to CNTs; and (iii) an approach to reduce or avoid the decrease in the electrical conductivity of CNTs accompanied with surface modification. As shown in Figure 2, this article gives a focused review of our efforts aiming to provide solutions to the aforementioned problems encountered with CNT modification and preparation of CNT-based nanocomposites.

Our development of carbon nanotubes modification/functionalization discussed in this focused review. (a) ATRA/ATRP mediated method, (b) ozone-mediated method, and (c) thermally-reversible Diels-Alder reaction mediated method. A full color version of this figure is available at Polymer Journal online.

Modification of CNTs with atom transfer radical addition/polymerization

The incorporation of polymer chains into CNTs results in CNT-polymer nanohybrid materials that possess the properties of CNTs and the attached polymers. Building up controlled and well-defined polymer architectures on CNT surfaces is therefore attractive for the preparation of materials with specific structures and properties. Atom transfer radical polymerization (ATRP) is an effective and convenient method for well-defined polymer synthesis. The combination of CNT modification and ATRP has been performed.29, 30, 31 A general approach involves the incorporation of ATRP initiating groups into the acid-oxidized CNT surfaces and sequential surface-initiated ATRP from the modified CNT surfaces.29 Block copolymers can be tethered to the CNTs through sequential ATRPs.30 Nevertheless, the approach involves the acid oxidation of CNTs and shows some limits to building the polymer architecture on CNTs. The active species of the atom transfer radical addition (ATRA) reaction is deactivated radicals, which are reactive toward the unsaturated C=C groups of CNTs.32 On the basis of this concept, we explored the first example of ATRA-mediated modification of CNTs (Figure 2a).33, 34 Both small molecules and long polymer chains, which possess ATRA active groups, have been chemically tethered to CNTs.33 Moreover, if a polymer chain possessing many ATRA active pendant groups is utilized as the reagent, the polymer chain is wound, rather than tethered, on the CNT surface.34 On the basis of this reaction, the first examples of engineering plastic polymer-modified CNTs, including poly(2,6-dimethylphenylene oxide),34 poly(ether sulfone)35 and poly(vinylidene difluoride) (PVDF),36 have been reported. Moreover, because some of the C–F groups of Nafion have recently been demonstrated to be ATRA active, Nafion-CNT nanohybrid materials have also been obtained.37 After the ATRA reaction, the halogen atom transfers from the ATRA agent to the CNTs. The resulting C-halogen groups on the CNT surfaces initiate ATRPs from the modified CNTs.33, 35 Surface-initiated ATRP is performed to introduce another polymer chain to the modified CNTs. As a result, different polymer structures, such as linear (co)polymer chains33 and V-shape block copolymer chains,33 can be chemically bonded to CNTs in different modes, such as tethering,33 winding24, 36, 37 and brushing.35 Furthermore, modification approach has also been applied to C60 to prepare multiblock polymer-C60 nanohybrids38, 39 and to graphene oxide to form versatile polymer architectures on graphene oxide surfaces.40

The ATRA-mediated approach provides a simple method to prepare versatile CNT-polymer nanohybrids. For example, it is convenient to impart amphiphilic characteristics to CNTs by tethering amphiphilic block copolymer chains to CNTs. Incorporation of stimuli-responsive polymer chains to CNTs creates stimuli-responsive CNT-polymer nanohybrids (Figure 3).33 Moreover, the functionalized CNTs have been utilized as functional additives for polymers to alter or introduce functions to the resulting nanocomposites, which is in contrast to the conventional role of reinforcing fillers of CNTs in the CNT/polymer nanocomposites. One example demonstrated in our studies is the preparation of poly(styrene sulfonic acid)-functionalized multi-walled CNTs (PSSA-MWCNT) as a functional additive for the fabrication of chitosan/MWCNT nanocomposite membranes used in pervaporative dehydration on ethanol aqueous solutions.41 The PSSA chains act as crosslinking agents for chitosan through the reaction between the sulfonic acid groups of PSSA and the amino groups of chitosan to stabilize the corresponding chitosan/MWCNT membranes. The MWCNTs also serve as rigid toughening agents.36 As a result, both the mechanical strength and the toughness of the chitosan/MWCNT membranes have been simultaneously increased by PSSA-MWCNT modification. When utilized in pervaporative dehydration on a 90 wt% ethanol aqueous solution, the crosslinked nanocomposite membrane shows a 5.4-fold separation factor compared with the neat chitosan membrane, without a significant decrease in the permeation fluxes.41 The hydrophilic features of the PSSA-MWCNT additive maintain the high flux of the membrane. This study provides a solution to the trade-off problems of (i) toughening polymeric materials accompanied with scarifying mechanical strength and (ii) stabilization of the pervaporative dehydration membrane to enhance the separation performance accompanied with decreases in the permeation fluxes. Another example has been demonstrated with MWCNTs functionalized with poly(sulfone) (PSF) and hydrophilic protein-resistant poly(sulfobetaine methacrylate) (PSBMA)42 (coded as MWCNT-PSF/PSBMA) prepared by the sequential ATRA of chloromethylated PSF to MWCNTs and the ATRP of SBMA initiated from MWCNT-PSF.35 When added to PSF membranes, the PSF portion of MWCNT-PSF/PSBMA provides compatibility with the PSF matrix, and the hydrophilic and protein-resistant PSBMA chains promote the MWCNT-PSF/PSBMA moving toward the membrane surface and introducing protein-resistant features to the membrane. Compared with the neat PSF membrane, the MWCNT-PSF/PSBMA-modified membrane exhibits 7% protein absorption and enhanced anti-fouling properties in bio-separation (Figure 3).35 As a result, the ATRA-mediated functionalization of MWCNTs is convenient and effective to construct polymer architecture and to introduce multi-functional polymer chains to MWCNTs. The obtained MWCNT hybrids are effective additives for the design and preparation of functional MWCNT/polymer nanocomposites.

(a) SEM micrograph of polystyrene-modified MWCNTs prepared by the surface-initiated ATRP of styrene, showing the presence of the cap of the MWCNT bundle.32 (b) Thermally responsive MWCNTs functionalized with polystyrene and poly(N-methyisopropylacrylamide) prepared with sequential ATRA and ATRP reactions.32 Functionalized MWCNTs are effective additives for the preparation of (c) protein-absorption-resistant and (d) anti-fouling membranes.35

Ozone-mediated preparation of CNT-polymer nanohybrids materials

The ATRA-mediated method could chemically bond existing polymer chains to CNTs only for polymer chains possessing ATRA-reactive pendant groups. This approach is not applicable to most engineering thermoplastics because they do not possess chemically reactive groups. For a CNT-reinforced nanocomposite, the interfacial compatibility between the polymer matrix and the CNTs, and the efficiency of the loading-stress transfer from the CNTs to the polymer matrix would be highly enhanced if the CNTs were modified with the matrix polymer chains.43 Hence, a CNT modification route, which could bond a wide range of polymer chains to CNTs, is highly expected and has been demonstrated with an ozone-mediated MWCNT functionalization (Figure 2b).44 Polymer chains in a suitable solution are treated with ozone to generate peroxide and hydroperoxide groups on the chains.45, 46 Thermal decomposition of the peroxide groups forms radicals, which are reactive toward MWCNTs.32 Consequently, the radical-possessing polymer chains react toward MWCNTs, resulting in polymer-functionalized MWCNT nanohybrids. This reaction route is applicable to most polymers that are soluble in a certain liquid mediate, including organic solvents and water, to significantly extend the scope of MWCNT-polymer nanohybrid materials. This method provides a general route to prepare matrix-polymer-modified MWCNTs for the preparation of the corresponding MWCNT-polymer nanocomposites. For MWCNT/PVDF nanocomposites, samples with PVDF-functionalized MWCNTs (the matrix-polymer-modified MWCNTs) exhibit superior mechanical strength compared with samples with PSF-functionalized MWCNTs,44 based on the relatively high stress-transfer efficiency from MWCNTs to the polymer matrix that results from the higher interfacial compatibility between PVDF-functionalized MWCNTs and the PVDF matrix (Figure 4). Moreover, the matrix-polymer-modified MWCNT is effective for toughening polymers.36 Compared with the neat electrospun poly(lactide) (PLA) nanofiber mat, the sample containing 0.3 wt% MWCNT-PLA exhibits twofold mechanical strength and sixfold strain in an instron test. The toughness of the PLA nanofiber mat has been enhanced ~12 times by modification with 0.3 wt% PLA-modified MWCNTs.47

(a) Stress-strain curves and (b) stress-loading transfer efficiency of MWCNT-reinforced polymer nanocomposite films showing the effect of matrix-polymer-modified MWCNTs.44

The ozone-mediated method opens a pathway to chemically incorporate the commercial product of non-reactive functional polymers into MWCNTs. The functional polymer layer wrapped on the MWCNT surface performs specific functions along the MWCNT bundles. Consequently, polyelectrolytes, including Nafion48, 49 and polybenzimidazole (PBI),50 which are raw materials for proton-exchange membranes of fuel cells, have been chemically bonded to MWCNTs, although they are non-reactive and were not previously reacted with MWCNTs. The Nafion-functionalized MWCNT is highly compatible with the Nafion matrix and is able to induce the sulfonic acid groups of Nafion chains on the MWCNT surfaces to create long-range, proton-conducting pathways in the resulting Nafion/Nafion-functionalized MWCNT nanocomposite membranes. Thereby, the nanocomposite membrane shows a high proton conductivity of five times the value recorded on the neat Nafion membrane (Figure 5).48 The proton conductivity exceeds the value measured with the commercial Nafion 212 membrane. A similar result has also been shown with the MWCNT-PBI/PBI nanocomposite membrane, which demonstrates twofold proton conductivity compared with the neat PBI membrane.50 The nanocomposite membranes also exhibit superior mechanical properties with both, enhanced stress strength and increased strain. As a result, the polyelectrolyte membranes have been simultaneously reinforced and toughened. Moreover, the methodology is effective for hydroxyl ion (OH−) conductive membranes for direct alkaline methanol fuel cells. The addition of the polyelectrolyte-modified MWCNTs to the polyelectrolyte-based membranes significantly increases their OH− ion conductivity and depresses their methanol permeability.51, 52 The nanocomposite membranes exhibit a high-power density of 105 mW cm−2 in single cell tests,52 which is much higher than the values recorded on the corresponding neat membranes (~10–20 mW cm−2). The results suggest that the functional polymer-modified MWCNTs are effective additives to create material-transporting pathways in polymer membranes.

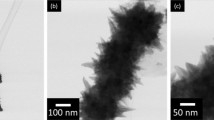

(a) High-resolution TEM micrograph of Nafion-functionalized MWCNTs prepared by an ozone-mediated process. (b) The Nafion-functionalized MWCNTs are effective additives for Nafion membranes to enhance proton conductivity.48

Thermally reversible modification of CNTs By Diels–Alder reactions

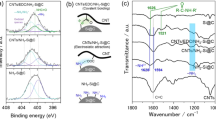

The Diels–Alder (DA) reaction is a thermally reversible 2+4 cyclization reaction involving a diene group and a dienophile group. Because CNTs possess many unsaturated C=C groups, functionalization of CNTs through the DA reaction has attracted researchers’ attention. The previous reports used modified CNTs to enhance their reactivity in the DA reaction-mediated modification. Sakellariou et al.53, 54 used benzocyclobutene derivatives to directly react MWCNTs by the DA reaction. We have demonstrated that furan (a diene) and maleimide (a dienophile) groups are highly reactive toward the unsaturated C=C groups of MWCNTs.55 The result supports that MWCNTs could serve as either a diene or a dienophile in the DA reaction-mediated surface functionalization. Because the DA reaction does not interfere with other reactive groups, the DA-mediated approach is convenient to introduce additional functional and reactive groups to MWCNTs, such as carboxylic acid, hydroxyl, amino and epoxide groups. The functionalized MWCNTs are useful agents for further chemical reactions and functionalization.56 Moreover, the reaction route is effective for the preparation of MWCNT-polymer nanohybrid materials. Polymer chains, which possess furan or maleimide pendant groups, can be directly incorporated into MWCNT surfaces.55 Moreover, based on the thermally reversible feature of the DA reaction, the thermal reversibility of MWCNT functionalization has been demonstrated (Figure 2c). De-functionalization of the modified MWCNTs could be achieved by thermal treatment at ~160 °C with the performance of the retro-DA reaction.55 The organic moieties detach from the modified MWCNTs to recover the pristine MWCNTs (Figure 6).

The upper part shows the pictures showing the effect of the thermally reversible modification of MWCNTs through the Diels–Alder (DA) and retro-DA reactions on the compatibility of MWCNTs with organic solvent. The lower part shows the electrical conductivity of the nanocomposites of PVDF and the DA-reaction-modified MWCNTs. Thermal treatment induces the de-modification of MWCNTs, resulting in a dramatic increase in the electrical conductivity of the nanocomposite.55

One of the attractive properties expected for the MWCNT/polymer nanocomposites is electrical conductivity.57 The neat (non-modified) MWCNTs can be used for the preparation of conductive polymer nanocomposites because chemical modification usually destroys the conjugate structure of MWCNTs to decrease their electrical conductivity. Nevertheless, this might not make sense because the surface modification of MWCNTs is required to improve the interfacial compatibility in the corresponding nanocomposites. This is a general problem for the preparation of electrically conductive MWCNT/polymer nanocomposites. The thermal reversibility of the DA reaction-mediated MWCNT modification has provided an effective solution to this problem. The methodology of this solution is performable within (i) the modification of MWCNTs with DA reactions to improve the organo-compatibility of MWCNTs, (ii) the preparation of MWCNT/polymer nanocomposites with the DA-adduct-modified MWCNTs without dispersion and the interfacial compatibility problem, and (iii) the thermal treatment of the nanocomposites at temperatures to induce the de-modification of MWCNTs through the retro-DA reaction and to regenerate the pristine MWCNTs, which have high electrical conductivity in the nanocomposites.58 The efficiency of this method for the preparation of highly electrically conductive MWCNT/polymer nanocomposites has been demonstrated with a maleimide-MWCNT/PVDF nanocomposite containing 0.5 wt% of maleimide-MWCNT. The nanocomposite shows an electrical conductivity of ~2 × 10−12 S cm−1 at room temperature. After being thermally treated, the electrical conductivity of the nanocomposite increases to ~5 × 10−8 S cm−1 because the maleimide groups are detached from the maleimide-MWCNTs to recover the chemical structure and electrical conductivity of MWCNTs (Figure 6). For the sample containing 1.0 wt% of maleimide-MWCNTs, thermal treatment increases the electric conductivity from 8 × 10−11 to 3 × 10−7 S cm−1.58 A relatively small amount of MWCNTs is enough to result in MWCNT/polymer nanocomposites with high electrical conductivity.

Conclusions

The author has demonstrated some new approaches to chemically incorporate organic moieties and polymer chains into MWCNTs. The methods provide high flexibility and convenience in design and synthesis for a wide range of MWCNT-polymer nanohybrid materials, which are difficult or impossible to obtain by the conventional routes for MWCNT modification. The unique MWCNT-polymer nanohybrids impart attractive properties and specific functions to the corresponding MWCNT/polymer nanocomposites to extend the scope and application of the CNT/polymer nanocomposites. I believe that more possibilities and examples should be explored for CNT-based materials based on the developed methods of MWCNT functionalization.

References

Gangopadhyay, R. & De, A. Conducting polymer nanocomposites: a brief overview. Chem. Mater. 12, 608–622 (2000).

Laine, R. M., Choi, J. & Lee, I. Organic-inorganic nanocomposites with completely defined interfacial interactions. Adv. Mater. 13, 800–803 (2001).

Zeng, Q. H., Yu, A. B., Lu, G. Q. & Paul, D. R. Clay-based polymer nanocomposites: research and commercial development. J. Nanosci. Nanotechnol. 5, 1574–1592 (2005).

Paul, D. R. & Robeson, L. M. Polymer nanotechnology: nanocomposites. Polymer 49, 3187–3204 (2008).

Camargo, P. H. C., Satyanarayana, K. G. & Wypych, F. Nanocomposites: synthesis, structure, properties and new application opportunities. Mater. Res. 12, 1–39 (2009).

Mittal, G., Dhand, V., Rhee, K. Y., Park, S. J. & Lee, W. R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 21, 11–25 (2015).

Chee, W. K., Lim, H. N., Huang, N. M. & Harrisond, I. Nanocomposites of graphene/polymers: a review. RSC Adv. 5, 68014–68051 (2015).

Colemana, J. N., Khana, U., Blaua, W. J. & Gun’ko, Y. K. Small but strong: a review of the mechanical properties of carbon nanotube–polymer composites. Carbon 44, 1624–1652 (2006).

Ma, P. C., Siddiqui, N. A., Marom, G. & Kim, J. K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: a review. Compos. Part A 41, 1345–1367 (2010).

Han, Z. & Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: a review. Prog. Polym. Sci. 36, 914–944 (2011).

Rahmat, M. & Hubert, P. Carbon nanotube–polymer interactions in nanocomposites: a review. Compos. Sci. Technol. 72, 72–84 (2011).

Pandey, G. & Thostenson, E. T. Carbon nanotube-based multifunctional polymer nanocomposites. Polym. Rev. 52, 355–416 (2012).

Liu, Y. & Kumar, S. Polymer/carbon nanotube nano composite fibers–a review. ACS Appl. Mater. Interfaces 6, 6069–6087 (2014).

Liew, K. M., Lei, Z. X. & Zhang, L. W. Mechanical analysis of functionally graded carbon nanotube reinforced composites: a review. Compos. Struct. 120, 90–97 (2015).

Meuer, S., Braun, L., Schilling, T. & Zentel, R. α-Pyrene polymer functionalized multiwalled carbon nanotubes: Solubility, stability and depletion phenomena. Polymer 50, 154–160 (2009).

Satake, A., Miyajima, Y. & Kobuke, Y. Porphyrin-carbon nanotube composites formed by noncovalent polymer wrapping. Chem. Mater. 17, 716–724 (2005).

Bartelmess, J., Ballesteros, B., de la Torre, G., Kiessling, D., Campidelli, S., Prato, M., Torres, T. & Guldi, D. M. Phthalocyanine-pyrene conjugates: a powerful approach toward carbon nanotube solar cells. J. Am. Chem. Soc. 132, 16202–16211 (2010).

Chen, G. Z., Shaffer, M. S. P., Coleby, D., Dixon, G., Zhou, W., Fray, D. J. & Windle, A. H. Carbon nanotube and polypyrrole composites: coating and doping. Adv. Mater. 12, 522–526 (2000).

Baykal, B., Ibrahimova, V., Er, G., Bengu, E. & Tuncel, D. Dispersion of multi-walled carbon nanotubes in an aqueous medium by water-dispersible conjugated polymer nanoparticles. Chem. Commun. 46, 6762–6764 (2010).

Zhao, H., Yuan, W. Z., Mei, J., Tang, L., Liu, X. Q., Yan, J. M., Shen, X. Y., Sun, J. Z., Qin, A. & Tang, B. Z. Enhanced dispersion of nanotubes in organic solvents by donor–acceptor interaction between functionalized poly(phenylacetylene) chains and carbon nanotube walls. J. Polym. Sci. Part A: Polym. Chem. 47, 4995–5005 (2009).

Monthioux, M., Smith, B. W., Burteaux, B., Claye, A., Fischer, J. E. & Luzzi, D. E. Sensitivity of single-wall carbon nanotubes to chemical processing: an electron microscopy investigation. Carbon 39, 1251–1272 (2001).

Hu, H., Zhao, B., Itkis, M. E. & Haddon, R. C. Nitric acid purification of single-walled carbon nanotubes. J. Phys. Chem. B 107, 13838–13842 (2003).

Datsyuk, V., Kalyva, M., Papagelis, K., Parthenios, J., Tasis, D., Siokou, A., Kallitsisa, I. & Galiotis, C. Chemical oxidation of multiwalled carbon nanotubes. Carbon 46, 833–840 (2008).

Zhang, J., Zou, H., Qing, Q., Yang, Y., Li, Q., Liu, Z., Guo, X. & Du, Z. Effect of chemical oxidation on the structure of single-walled carbon nanotubes. J. Phys. Chem. B 107, 3712–3718 (2003).

Ziegler, K. J., Gu, Z., Peng, H., Flor, E. L., Hauge, R. H. & Smalley, R. E. Controlled oxidative cutting of single-walled carbon nanotubes. J. Am. Chem. Soc. 127, 1541–1547 (2005).

Holzinger, M., Vostrowsky, O., Hirsch, A., Hennrich, F., Kappes, M., Weiss, R. & Jellen, F. Sidewall functionalization of carbon nanotubes. Angew. Chem. Int. Ed. 40, 4002–4005 (2001).

Sun, Y. P., Fu, K., Lin, Y. & Huang, W. Functionalized carbon nanotubes: properties and applications. Acc. Chem. Res. 35, 1096–1104 (2002).

Banerjee, S., Hemraj-Benny, T. & Wong, S. S. Covalent surface chemistry of single-walled carbon nanotubes. Adv. Mater. 17, 17–29 (2005).

Kong, H., Gao, C. & Yan, D. Controlled functionalization of multiwalled carbon nanotubes by in situ atom transfer radical polymerization. J. Am. Chem. Soc. 126, 412–413 (2004).

Kong, H., Gao, C. & Yan, D. Constructing amphiphilic polymer brushes on the convex surfaces of multi-walled carbon nanotubes by in situ atom transfer radical polymerization. J. Mater. Chem. 14, 1401–1405 (2004).

Matyjaszewski, K. & Tsarevsky, N. V. Nanostructured functional materials prepared by atom transfer radical polymerization. Nat. Chem. 1, 276–288 (2009).

Liu, Y., Yao, Z. & Adronov, A. Functionalization of single-walled carbon nanotubes with well-defined polymers by radical coupling. Macromolecules 38, 1172–1179 (2005).

Liu, Y. L. & Chen, W. H. Modification of multi-wall carbon nanotubes with initiators and macro-initiators of atom transfer radical polymerization. Macromolecules 40, 8881–8886 (2007).

Liu, Y. L., Chang, Y. H. & Liang, M. Poly(2,6-dimethyl-1,4-phenylene oxide) (PPO) multi-bonded carbon nanotube (CNT): preparation and formation of PPO/CNT nanocomposites. Polymer 49, 5404–5409 (2008).

Liu, Y. L., Chang, Y., Chang, Y. H. & Shih, Y. J. Preparation of amphiphilic polymer-functionalized carbon nanotubes for low-protein-adsorption surfaces and protein-resistant membranes. ACS Appl. Mater. Interfaces 2, 3642–3647 (2010).

Chang, C. M., Hsu, K. Y. & Liu, Y. L. Matrix-polymer-functionalized multiwalled carbon nanotube as a highly efficient toughening agent for the matrix polymer. J. Polym. Sci. Part B: Polym. Phys. 50, 1151–1155 (2012).

Peng, K. J., Wang, K. H., Hsu, K. Y. & Liu, Y. L. Atom transfer radical addition/polymerization of perfluorosulfonic acid polymer with the C-F bonds as reactive sites. ACS Macro Lett. 4, 197–201 (2015).

Liu, Y. L., Chang, Y. H. & Chen, W. H. Preparation and self-assembled toroids of amphiphilic polystyrene-C60-poly(N-isopropylacrylamide) block copolymers. Macromolecules 41, 7857–7862 (2008).

Peng, K. J. & Liu, Y. L. Preparation and toroid formation of multiblock polystyrene/C60 nanohybrids. Macromolecules 44, 5006–5012 (2011).

Peng, K. J., Wang, K. H., Hsu, K. Y. & Liu, Y. L. Building up polymer architectures on graphene oxide sheet surfaces through sequential atom transfer radical polymerization. J. Polym. Sci. Part A: Polym. Chem. 52, 1588–1596 (2014).

Liu, Y. L., Chen, W. H. & Chang, Y. H. Preparation and properties of chitosan/carbon nanotube nanocomposites using poly(styrene sulfonic acid)-modified CNTs. Carbohydrate Polym. 76, 232–238 (2009).

Chiang, Y. C., Chang, Y., Higuchi, A., Chen, W. Y. & Ruaan, R. C. Sulfobetaine-grafted poly(vinylidene fluoride) ultrafiltration membranes exhibit excellent antifouling property. J. Membr. Sci. 339, 151–159 (2009).

Lin, Y., Zhou, B., Fernando, K. A. S., Liu, P., Allard, L. F. & Sun, Y. P. Polymeric carbon nanocomposites from carbon nanotubes functionalized with matrix polymer. Macromolecules 36, 7199–7204 (2003).

Chang, C. M. & Liu, Y. L. Functionalization of multi-walled carbon nanotubes with non-reactive polymers through an ozone-mediated process for the preparation of a wide range of high performance polymer/carbon nanotube composites. Carbon 48, 1289–1297 (2010).

Liu, Y. L., Lin, G. C. & Wu, C. S. Facile approach to functionalize polymers with specific chemical groups by ozone treatment: preparation of cross-linkable poly(vinylidene fluoride) possessing benzoxazine pendent groups. J. Polym. Sci. Part A: Polym. Chem. 45, 949–954 (2007).

Wang, W. C., Vora, R. H., Kang, E. T., Neoh, K. G., Ong, C. K. & Chen, L. F. Nanoporous ultra-Low-k films prepared from fluorinated polyimide with grafted poly(acrylic acid) side chains. Adv. Mater. 16, 54–57 (2004).

Li, H. Y., Chang, C. M., Hsu, K. Y. & Liu, Y. L. Poly(lactide)-functionalized and Fe3O4 nanoparticle-decorated multiwalled carbon nanotubes for preparation of electrically-conductive and magnetic poly(lactide) films and electrospun nanofibers. J. Mater. Chem. 22, 4855–4860 (2012).

Liu, Y. L., Su, Y. H., Chang, C. M., Suryani, S., Wang, D. M. & Lai, J. Y. Preparation and applications of Nafion-functionalized multiwalled carbon nanotubes for proton exchange membrane fuel cells. J. Mater. Chem. 20, 4409–4416 (2010).

Chang, C. M., Li, H. Y., Lai, J. Y. & Liu, Y. L. Nanocomposite membranes of Nafion and Fe3O4-anchored and Nafion-functionalized multiwalled carbon nanotube exhibiting high proton conductivity and low methanol permeability for direct methanol fuel cells. RSC Advances 3, 12895–12904 (2013).

Suryani, S., Chang, C. M., Liu, Y. L. & Lee, Y. M. Polybenzimidazole membranes modified with polyelectrolyte-functionalized multiwalled carbon nanotubes for proton exchange membrane fuel cells. J. Mater. Chem. 21, 7480–7486 (2011).

Lo, C. F., Wu, J. F., Li, H. Y., Hung, W. S., Shih, C. M., Hu, C. C., Liu, Y. L. & Lue, S. J. Novel polyvinyl alcohol nanocomposites containing carbon nano-tubes with Fe3O4 pendants for alkaline fuel cell applications. J. Membr. Sci. 444, 41–49 (2013).

Wu, J. F., Lo, C. F., Li, L. Y., Li, H. Y., Chang, C. M., Laio, K. S., Hu, C. C., Liu, Y. L. & Lue, S. J. Thermally stable polybenzimidazole/carbon nano-tube composites for alkaline direct methanol fuel cell applications. J. Power Sources 246, 39–48 (2014).

Sakellariou, G., Ji, H., Mays, J. W., Hadjichristidis, N. & Baskaran, D. Controlled covalent functionalization of multiwalled carbon nanotubes using [4+2] cycloaddition of benzocyclobutenes. Chem. Mater. 19, 63706372 (2007).

Sakellariou, G., Ji, H., Mays, J. W. & Baskaran, D. Enhanced polymer grafting from multiwalled carbon nanotubes through living anionic surface-initiated polymerization. Chem. Mater. 20, 6217–6230 (2008).

Chang, C. M. & Liu, Y. L. Functionalization of multi-walled carbon nanotubes with furan and maleimide compounds through Diels-Alder cycloaddition. Carbon 47, 3041–3049 (2009).

Wang, Y. H., Chang, C. M. & Liu, Y. L. Benzoxazine-functionalized multi-walled carbon nanotubes for preparation of electrically-conductive polybenzoxazines. Polymer 53, 106–112 (2012).

Bauhofer, W. & Kovacs, J. Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 69, 1486–1498 (2009).

Chang, C. M. & Liu, Y. L. Electrical conductivity enhancement of polymer/multi-walled carbon nanotube (MWCNT) composites by thermally-induced de-functionalization of MWCNTs. ACS Appl. Mater. Interface 3, 2204–2208 (2011).

Acknowledgements

I thank all coworkers of the published papers discussed in this review and the Ministry of Science and Technology, Taiwan for the financial support of this work (Grant No 99-2221-E-007-128-MY3, 100-2221-E-007-127-MY3 and 102-2221-E-007-135-MY3).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The author declares no conflict of interest.

Rights and permissions

About this article

Cite this article

Liu, YL. Effective approaches for the preparation of organo-modified multi-walled carbon nanotubes and the corresponding MWCNT/polymer nanocomposites. Polym J 48, 351–358 (2016). https://doi.org/10.1038/pj.2015.132

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/pj.2015.132

This article is cited by

-

Construction of micro-thermal conductive network of self-assembled CNTs hybrids with 1D–0D structure

Journal of Thermal Analysis and Calorimetry (2022)

-

Carbon-based nano-filler in polymeric composites for supercapacitor electrode materials: a review

Environmental Science and Pollution Research (2021)

-

Cyclic voltammetry for the determination of the selectivity of PANI-HClO4 sensor to different acids

Ionics (2020)

-

Enhancing the Co gas sensing properties of ZnO thin films with the decoration of MWCNTs

Journal of Materials Science: Materials in Electronics (2019)

-

High-performance SPEEK/SWCNT/fly ash polymer electrolyte nanocomposite membranes for fuel cell applications

Polymer Journal (2017)