Abstract

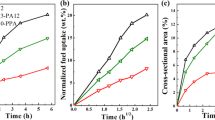

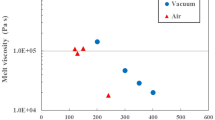

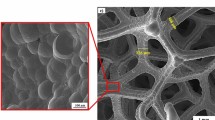

Polyamide 11 (PA11), a 100% biobased plastic derived from inedible plants, and polypropylene (PP) were mixed with a reactive compatibilizer using a twin-screw extruder. The mechanical properties and morphology of the resulting injection-molded PP/PA11 bioalloys were investigated by flexural tests, Charpy notched impact tests, field-emission scanning electron microscopy (FE-SEM), and transmission electron microscopy (TEM), among other tests. We found that it was possible to control the morphology of the bioalloy and that it had a wide range of mechanical properties depending on the morphology. When the morphology of the bioalloy was a “ nanosalami” structure, as revealed by FE-SEM, the material had a Charpy notched impact strength of 70–85 kJ/m2, which is superior to that of polycarbonates, without a large reduction in the flexural modulus. TEM observations showed that the reactive compatibilizers were located in the interphase between the matrix and dispersed phase. The compatibilizers played a key role in improving impact strength. The bioalloy could be used for foam injection molding; therefore, it was able to be applied as a foamed door trim, resulting in an approximately 30% weight reduction for the plastic part.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

MacArthur E. Beyond plastic waste. Science 2017;358:843.

https://www.undp.org/united-states/sustainable-development-goals. Accessed 31 Aug 2022.

https://global.toyota/en/sustainability/esg/challenge2050/?_ga=2.54814819.95233906.1661070302-695201248.1658734777. Accessed 31 Aug 2022.

Lim LT, Auras R, Rubino M. Processing technologies for poly(lactic acid). Prog Polym Sci. 2008;33:820–2.

Nampoothiri KM, Nair NR, John RP. An overview of the recent developments in polylactide (PLA) research. Bioresour Technol. 2010;101:8493–501.

Lenz RW, Marchessault RH. Bacterial polyesters: Biosynthesis, biodegradable plastics and biotechnology. Biomacromolecules 2005;6:1–8.

Iwata T. Biodegradable and bio-based polymers: Future prospects of eco-friendly plastics. Angew Chem Int Ed. 2015;54:3210–5.

Lütke-Eversloh T, Fischer A, Remminghorst U, Kawada J, Marchessault RH, Boögershausen A, et al. Biosynthesis of novel thermoplastic polythioesters by engineered Escherichia coli. Nat Mater. 2002;1:236–40.

Sano H, Usami T, Nakagawa H. Lamellar morphologies of melt-crystallized polyethylene, isotactic polypropylene and ethylene-propylene copolymers by the Ru04 staining technique. Polymer 1986;27:1497–504.

Kawada J, Kitou M, Mouri M, Mitsuoka T, Araki T, Lee CH, et al. Morphology controlled PA11 bio-alloys with excellent impact strength. ACS Sustain. Chem Eng. 2016;4:2158–64.

Donald AM, Kramer EJ. Craze initiation and growth in high-impact polystyrene. J Appl Polym Sci. 1982;27:3729–41.

Fischer M, Hellmann GP. On the evolution of phase patterns during the high-impact-modified polystyrene process. Macromolecules 1996;29:2498–509.

Kawada J, Kitou M, Mouri M, Kato Y, Katagiri Y, Matsushita M, et al. Super impact absorbing bio-alloys from inedible plants. Green Chem. 2017;19:4503–8.

Ide F, Hasegawa A. Studies on polymer blend of nylon 6 and polypropylene or nylon 6 and polystyrene using the reaction polymer. J Appl Polym Sci. 1974;18:963–74.

Gupta AK, Purwar SN. Crystallization of PP in PP/SEBS blends and its correlation with tensile properties. J Appl Polym Sci. 1984;29:1595–609.

Wu S. Phase structure and adhesion in polymer blends: A criterion for rubber toughening. Polymer 1985;26:1855–63.

Wu S. A generalized criterion for rubber toughening: The critical matrix ligament thickness. J Appl Polym Sci. 1988;35:549–61.

Wu S. Chain structure, phase morphology, and toughness relationships in polymers and blends. Polym Eng Sci. 1990;30:753–61.

Muratoglu OK, Argon AS, Cohen RE, Weinberg M. Toughening mechanism of rubber-modified polyamides. Polymer 1995;36:921–30.

https://www.chemistryworld.com/news/castable-polymers-made-from-castor-beans/3007982.article. Accessed 31 Aug 2022.

https://www.toyota-boshoku.com/global/news/6783.html. Accessed 31 Aug 2022.

Acknowledgements

The authors are grateful to Dr. Arimitsu Usuki and Mr. Osamu Kitou for their enormous guidance, strong encouragement, and continuous support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kawada, J., Kitou, M., Mouri, M. et al. Invention of biobased polymer alloys and their application in plastic automobile parts. Polym J 55, 753–760 (2023). https://doi.org/10.1038/s41428-023-00760-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-023-00760-1