Abstract

The strength of subducted slabs in the mantle transition zone influences the style of mantle convection. Intense deformation is observed particularly in relatively old subducted slabs in the deep mantle transition zone. Understanding the cause of this regional and depth variation in slab deformation requires constraint of the rheological properties of deep mantle materials. Here, we report results of in situ deformation experiments during the olivine to ringwoodite phase transformation, from which we infer the deformation process under the conditions of cold slabs deep in the mantle transition zone. We find that newly transformed fine-grained ringwoodite deforms by diffusion creep and that its strength is substantially smaller than that of coarser-grained minerals but increases with time. Scaling analysis, based on a model of transformation kinetics and grain-size evolution during a phase transformation, suggests that a cold slab will be made of a mixture of weak, fine-grained and strong, coarse-grained materials in the deep transition zone, whereas a warm slab remains strong because of its large grain size. We propose that this temperature dependence of grain size may explain extensive deformation of cold slabs in the deep transition zone but limited deformation of relatively warm slabs.

Similar content being viewed by others

Main

Rheological properties of mantle materials are highly temperature sensitive; hence cold and strong regions exert high resistance to deformation and therefore provide an important control on the style and energetics of mantle convection. High-resolution tomographic images show intense deformation of subducting slabs in the mantle transition zone, particularly in the western Pacific where old and cold slabs subduct1. This is an enigmatic observation since cold slabs would be strong if normal temperature sensitivity of rheological properties is assumed2. In addition, when evidence of deformation is observed, it is in many cases in the deep transition zone.

Phase transformations occur in mantle minerals in the transition zone3, and therefore intense deformation of slabs in the mantle transition zone is most likely associated with phase transformations. Among various processes associated with a phase transformation2,4, grain-size reduction potentially has the largest effect on rheological properties2. However, in the previous study by Karato et al.2, both grain size after transformation and the rheological properties of transition zone minerals were either estimated theoretically or inferred from the experimental results on analog materials. Consequently, both the degree of weakening and the depth range where weakening may occur remain highly uncertain.

Olivine is a volumetrically dominant mineral in the upper mantle (~60%) that undergoes phase transformations to its high-pressure polymorphs3: olivine first transforms to wadsleyite at ~410 km and then to ringwoodite at ~520 km. However, in the cold interiors of subducting slabs, olivine probably transforms directly to ringwoodite as a consequence of sluggish kinetics of olivine to wadsleyite phase transformation at low temperatures5,6; we therefore focus on the influence of olivine to ringwoodite phase transformation. When phase transformation takes place after a large overshoot beyond the equilibrium phase boundary (for example, directly from olivine to ringwoodite), the resultant grain size is small, particularly at low temperatures2,7,8,9.

Experimental procedure

We measured the creep strength of coexisting olivine and ringwoodite under conditions equivalent to the cold slabs in the transition zone (pressure (P) = 15–18 GPa and temperature (T) = 750–1173 K). To observe the evolution of rheological behaviour during a phase transformation, only a very limited temperature range (~1,173 K) can be chosen (Supplementary Fig. 4). Deformation experiments were conducted using the rotational Drickamer apparatus in the torsion geometry by rotating the top anvil relative to the bottom anvil. Strain (and strain rate) and stress were measured by X-ray radiography and radial X-ray diffraction, respectively10,11.

Synchrotron in situ deformation experiments combined with a high-pressure deformation apparatus12,13 provide an opportunity to characterize the rheological properties under the deep Earth conditions. This includes not only the quantitative studies of rheological properties but also the determination of relative strength of two or more co-existing materials10. In addition, one can infer deformation mechanisms (either diffusion or dislocation-related creep) using a theory of radial X-ray diffraction14.

In a sample assembly, we load two samples: (1) olivine and (2) pre-synthesized ringwoodite (see Supplementary Figs. 1 and 2 for further details). The microstructure of starting materials and recovered samples is shown in Supplementary Fig. 2. The grain size of olivine was initially bimodal; coarse-grained regions have a grain size of ~1 μm, whereas in fine-grained regions the grain size is ~0.1 μm (Supplementary Fig. 2a). During a deformation experiment, fine-grained regions of olivine transformed to fine-grained ringwoodite (see more details in Supplementary Fig. 2). In contrast, grain size of coarse-grained olivine and pre-synthesized ringwoodite remained nearly constant (Table 1).

Pressure and temperature conditions are estimated from X-ray diffraction data of the molar volume of platinum15 and ringwoodite16 (Supplementary Fig. 3). A platinum foil was also used to track the strain (Supplementary Fig. 6). Strain rate and cumulative strain at the end of the experiment are reported in Table 1.

To determine stress, we measure lattice strain from the diffracted X-ray collected from two different regions (pre-synthesized ringwoodite and olivine that partially transformed to ringwoodite; Raman spectra of the recovered samples and the corresponding diffracted X-ray spectra are shown in Supplementary Fig. 5) using ten detectors located at different angles with respect to the sample coordinate (Supplementary Figs. 1 and 6). In the region where olivine partially transformed to ringwoodite, we determine the lattice strain for both olivine and ringwoodite. Measured orientation dependence of lattice strain was converted to stress acting on each mineral using the theory of Singh et al.17 and interpreted using a theory of Karato14. Lattice strain was measured for the (130) plane for olivine, and the (220), (440) and (311) planes are used for ringwoodite.

Evolution of creep strength in olivine and ringwoodite

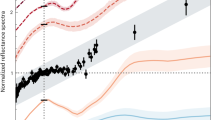

Estimated stress from samples in both the runs, AB12 and AB14, is plotted as a function of time in Fig. 1. The following three observations are critical. (1) Pre-synthesized ringwoodite and untransformed olivine are stronger than newly transformed fine-grained ringwoodite. (2) Strength of pre-synthesized ringwoodite is nearly independent of time (the same is true for olivine), whereas strength of newly transformed ringwoodite increases substantially with time. (3) Pre-synthesized ringwoodite shows strong (hkl) (diffraction plane) dependence of stress (~6 GPa for (220) and (440) and ~4 GPa for (311)), whereas in newly transformed ringwoodite, stress is nearly independent of (hkl).

Stress for pre-synthesized ringwoodite and olivine plus transformed ringwoodite from AB14 and AB12 is plotted as a function of time; stress estimated from different (hkl) planes is shown; errors represent one s.d. (obtained from uncertainty in fitting the peak position). The solid line shows that model 1 (see Methods) fit to the stress evolution in transformed ringwoodite. Diffracted X-ray from (130) plane in olivine and (220) plane in ringwoodite is not observed in AB12 because the signal was blocked. Stress shown here is equivalent stress (σE) defined by \(\sigma _{\mathrm{E}} = \sqrt {\sigma _{\mathrm{U}}^2 + \frac{3}{4}\sigma _{\mathrm{S}}^2}\), where σU is uniaxial stress and σS is the shear stress (Supplementary Information).

Because pre-synthesized and newly transformed ringwoodite have different grain size (newly transformed ringwoodite is ~10–20 nm (Supplementary Fig. 2d) and pre-synthesized ringwoodite is ~0.3–0.5 μm (Supplementary Fig. 2e)), it is conceivable that these differences in plastic properties are caused by the difference in grain size. One obvious explanation is that fine-grained ringwoodite deforms by diffusion creep while coarse-grained (pre-synthesized) ringwoodite deforms by one of the dislocation creep mechanisms. Observations (2) and (3) support this. The time dependence of lattice strain (strength) in fine-grained ringwoodite can be interpreted by the influence of grain-growth in diffusion creep regime. In addition, the strong (hkl) dependence of lattice strain for coarse-grained samples suggests dislocation creep mechanism, while the absence of (hkl) dependence of lattice strain in fine-grained samples suggests the operation of diffusion creep (for details, see ref. 14 and the Supplementary Information).

Modelling creep strength of transformed ringwoodite

In our sample assembly, newly formed fine-grained ringwoodite co-exists with untransformed olivine. In analysing the rheological properties of a two-phase mixture, one can consider two end-member cases: homogeneous stress and homogeneous strain. Observation (1) shows that stress is not homogeneous. And observation (2) suggests that deformation of each sample in our experiments took place at nearly homogeneous strain conditions; otherwise, stress (lattice strain) in the coarse-grained samples would evolve with time (Supplementary Information). In this case, volume fraction of transformed ringwoodite does not directly affect the rheology of each phase, and the observed time dependence of lattice strain reflects mostly the time dependence of strength of each phase.

On the basis of the evidence of (hkl) independence of stress, we conclude that deformation in these fine-grained parts occurs via diffusion creep. In diffusion creep, strength is dependent on grain size. In our model, we explain the observed time dependence of strength by grain growth. Using model 1 (a model explained in detail in the Methods, see also the Supplementary Information), we estimated the best parameters (diffusion coefficient and a coefficient for grain-growth kinetics) that explain the data. The results are shown in Fig. 2. The agreement of these estimated values from our experiments with the published values is excellent, supporting the validity of this model.

Model fitting was made using two parameters as unknowns: grain-growth rate (k) and diffusion coefficient (δDgb) (see the Methods and Supplementary Information). The combination of parameters that give the best fit (least chi-squared value) is marked with a red star. The colour bar represents the bounds for two s.d. around the best-fit value.

Rheological weakening of subducted slabs

To apply the present results to deformation of a slab in Earth’s deep interior, we need to examine a few issues. In the laboratory studies reported here, we found that diffusion creep dominates for a grain size less than ~50 nm. However, the critical grain size for diffusion creep will be different at the geological timescale. In addition, even though we now have a new dataset on deformation of fine-grained ringwoodite, we do not know how the formation of weak ringwoodite affects the rheological properties in a region where ringwoodite is formed. Finally, given the presence of a weak region in a slab, we need to understand how a whole slab deforms when it contains a complex rheological structure2.

To infer the deformation mechanisms in the subducting slab from laboratory data, we construct a deformation mechanism map for ringwoodite based on the available experimental data, including the present results (Supplementary Fig. 10). As discussed in detail in the Supplementary Information, there are large uncertainties in such a map, but we can infer that diffusion creep probably dominates under the deep slab conditions (cold conditions) when grain size is smaller than ~100 μm.

To evaluate the degree of weakening in a mixture of newly formed ringwoodite and untransformed olivine, we take the following approach. We first develop a model for the evolution of strength of transformed ringwoodite during deformation by diffusion creep, including the effect of ongoing phase transformation of olivine to ringwoodite and grain growth in transformed ringwoodite (Methods and section 4 in the Supplementary Information). We then use a model for the deformation of a two-phase aggregate similar to the one developed by Ponge-Gottstein18 to determine the strength of a two-phase aggregate containing both olivine and newly transformed fine-grained ringwoodite. In their model, a weak phase is formed along grain boundaries and the volume fraction of a weak phase increases with time (strain) (similar to the formation of small ringwoodite grains at olivine grain boundaries). We used threshold volume fractions of 10, 20 and 30%, above which the strength of the aggregate is controlled mostly by that of a weak phase (similar to the interconnected weak layer model by Handy19, for details see the Methods and Supplementary Information).

Using the model described, we evaluate the strength of a two-phase mixture in a realistic deep slab condition. We consider a cold slab where temperature at 660 km is 900 K and temperature at other depths follows the adiabatic gradient (0.6 K km–1). For this thermal model and with a plausible stress of ~300 MPa (ref. 20), if grain size remains ~5 mm (typical grain size in the mantle), there will be no appreciable deformation (strain rate is ~10−37 s−1 using the Peierls mechanism in olivine). However, when a phase transformation occurs in the coldest region of a slab, very small grains will be formed. Grain size after nucleation is estimated to be ~8 nm (grain size at ~370 km) (ref. 7), and the grain size at ~660 km is ~40 nm (due to grain growth during ongoing phase transformation) (Fig. 3b). Due to the combination of grain growth and the increase in volume fraction of fine-grained materials, the strength of the coldest region of an old slab evolves with depth. Evolution of strength of such a region is calculated on the basis of the previous studies on initial grain size7, diffusion coefficients21, grain growth rate22 and transformation kinetics23 (Fig. 3).

a, Volume fraction of transformed materials as a function of depth for a typical cold slab (broken lines show the threshold volume fractions assumed in this work; 10, 20, 30%). b, Grain size of ringwoodite during phase transformation versus depth. c, Strain rate versus depth in an olivine–ringwoodite aggregate assuming a stress of 300 MPa. Geologically important strain rate (>10−15 s−1) can be achieved below ~520–560 km depending on two parameters (threshold volume fraction and a parameter ‘α’ that represents the sharpness of the transition from iso-strain to iso-stress conditions (Methods)).

Weakening in the coldest region of a subducted slab starts as soon as fine grains are formed (~370 km), but because the connection of fine-grained regions is needed to weaken a composite, substantial weakening can be achieved only at ~520–560 km in this model. The estimated strain rate in the fine-grained regions is ~10−13 s−1, which results in geologically noticeable deformation, providing a natural explanation for the deformation of the coldest region of subducted slabs in the mantle transition zone (Fig. 3). In contrast, in warm slabs, phase transformation takes place near equilibrium conditions. In this case, the grain size of ringwoodite after the transformation is controlled by the Avrami length and is large (~1 mm for 1,100 K (refs. 7 and 9)). Consequently, weakening by grain-size reduction will not occur in warm slabs.

We now need to evaluate the role of weak regions in the central cold portion of a slab for the deformation of the whole slab. As shown by Karato et al.2, a subducted slab probably has a complex rheological structure caused mainly by the large variation in temperature, ranging from ~900 K to ~1,500 K. In the cold, near-central region, strength would be high and no appreciable deformation of slab is expected if grain-size reduction does not occur. However, a large grain-size reduction is expected in such a region, which substantially reduces the strength, as demonstrated in this work. The results of our experimental study and the calculations using our model largely agree with the previous theoretical model2 that showed that a weak region in the central portion of a slab substantially reduces the resistance to the deformation of a slab as a whole.

Finally, our experimental study and model suggest that a cold and deep slab probably has a highly heterogeneous strength, being made of a mixture of soft, fine-grained ringwoodite regions surrounded by much stronger regions with coarse-grained minerals resulting in large strength contrast. A material made of large strength contrast is susceptible to localized unstable deformation24,25. It is interesting to note that this depth corresponds to the region where deep earthquake activity is high26.

In summary, the present study demonstrates the usefulness of synchrotron-based in situ deformation experiments to characterize the rheological properties and their evolution under the deep mantle conditions. Our results strongly suggest the significance of grain-size reduction to enhance slab deformation. We showed that heterogeneous and evolving microstructure is formed during a phase transformation. The stability of deformation of such a material needs further investigation in connection to deep earthquakes.

Methods

Determining the strength of co-existing materials by in situ deformation experiments

In a classic deformation experiment, one applies macroscopic strain rate on a sample and measures the macroscopic stress acting on it to determine the relationship between macroscopic stress and strain rate. By contrast, in a synchrotron in situ deformation experiment, we measure diffracted X-ray from each phase in a sample assembly. In this particular study, a sample assembly contains several regions (untransformed coarse-grained olivine, pre-transformed coarse-grained ringwoodite and newly transformed fine-grained ringwoodite (Supplementary Information)).

Since these materials are packed together, they deform nearly homogeneously. This leads to heterogeneous stress distribution as observed. Consequently, the evolution of stress–strain distribution due to the increase in the volume of weak fine-grained ringwoodite cannot be determined in the present approach.

Inferring the deformation mechanisms from synchrotron in situ deformation experiments

The dependence of lattice strain on (hkl) comes from elastic and plastic anisotropy of the material14. If a material is elastically isotropic (such as ringwoodite under the present experimental conditions27), then (hkl) dependence of lattice strain comes only from plastic anisotropy14.

Plastic anisotropy depends on deformation mechanisms. In diffusion creep, lattice strain is independent of (hkl) because diffusion in a cubic crystal is isotropic. In contrast, in dislocation creep, (hkl) dependence could arise if plastic properties are anisotropic. Indeed, Hustoft et al.28 and Miyagi et al.29 showed that plasticity of ringwoodite is anisotropic when deformed by dislocation creep.

Therefore, the (hkl) dependence of lattice strain can provide evidence for the deformation mechanism: if lattice strain is dependent on (hkl), deformation is by dislocation creep; if lattice strain is independent of (hkl), then deformation is by diffusion creep or by dislocation creep with isotropic plasticity.

Another observation that we can use to infer deformation mechanism is the presence or absence of time hardening. When deformation is by diffusion creep, then time hardening will occur caused by grain growth30. By contrast, when deformation is by dislocation creep, nearly steady-state creep is observed after a short period of transient creep. We use these observations to infer operating deformation mechanisms in each material in a sample assembly (olivine, coarse-grained pre-transformed ringwoodite, fine-grained newly formed ringwoodite).

Modelling the influence of grain growth

As discussed in the main text, strength of newly formed ringwoodite increases with time (Fig. 1). This is due to grain growth that occurs during deformation. We analyse this using the equation:

where σ(t) is stress, A is a constant, \(\dot \varepsilon\) is imposed strain rate, Deff is effective diffusion coefficient (we assume grain-boundary diffusion), and in this case, \(D_{{\mathrm{eff}}} = {\textstyle{{\pi \delta } \over L}}D_{{\mathrm{gb}}}\) (δ, grain-boundary thickness; Dgb, grain-boundary diffusion coefficient) and L(t) is time-dependent grain size. For the time-dependent grain size, we use the following relation:

where k is grain-growth rate constant, t is time after the transformation, Lo is the initial grain size and m is the grain-size exponent. Since grain size evolves with time, strength of a material evolves with time.

The model

We consider two models regarding the influence of concurrent grain growth. In one model, we assume that the phase transformation is complete at the beginning of a deformation experiment. In this case, t is time measured from the beginning of a deformation experiment. However, the phase transformation may also occur during a deformation experiment. In this case, t is time after transformation, and therefore t in equation (2) should be replaced with t – to where to is time when a new grain is formed.

In this case, the average grain size of ringwoodite at any given time is given by the following relationship:

where to is the time of nucleation of a grain, L(t – t0) follows equation (2) and V(t) is the volume fraction transformed, which is given by:

where \(\dot G\) is the interface growth rate of the olivine–ringwoodite interface into olivine and Rinitial is the initial grain size of the transforming material (olivine).

Including the effects of ongoing phase transformation and grain growth, the equation to calculate the stress evolution with time during deformation by diffusion creep is given by:

Using equation (5), in the following sections, we model our experimental results and discuss the application of our model to Earth conditions.

Model fitting

We considered both cases (a case where transformation is completed before deformation and a case where transformation occurs during deformation) and explore the parameter space that can explain our observations. We found that a broad range of kinetic parameter (that is, the rate of growth of ringwoodite) can explain the observed data, and therefore transformation kinetics does not have a strong influence on hardening (Supporting Information).

We used the grid search method for a parameter space containing diffusion coefficient (δDgb), grain-growth rate (k) (m value for grain growth is assumed to be 4.5 as estimated by Yamazaki et al.22, initial grain size of nucleation (Lo) is assumed to be 8 nm following previous studies7) and the interface growth rate \(({\dot G})\).

For the first model (completed transformation before deformation), we use an equation simply combining equations (1) and (2) and determine which diffusion coefficient (δDgb) and grain-growth parameter (k) best explain the data.

For the second model (ongoing transformation during deformation), we use equation (5) to explain the stress versus time data from transformed ringwoodite (Fig. 1), and the parameters that we explored are diffusion coefficient (δDgb), grain-growth parameter (k) and the interface growth rate \(({\dot G})\).

Figure 2 shows the reduced chi-squared values (with the bounds for 2 s.d.) defined as follows:

where \(d_i^{{\mathrm{obs}}}\) is the observed data, \(d_i^{{\mathrm{pred}}}\) is the predicted value from the model and σxi is the error in \(d_i^{{\mathrm{obs}}}\) (shown in Fig. 1), a is the number of data points and b is the number of parameters being fit; for our model, b = 3 (grain-growth rate and diffusion coefficient and interface growth rate).

Since the matrix of parameter space for our model is three dimensional (3D), for the ease of illustration, we show the reduced chi-squared values for a combination of two parameters, keeping the third parameter fixed (Fig. 2). To this end, we first determine the values of parameters that fit our data best (a point in 3D space); we then take slices of a combination of two parameters passing through this best fit value giving a 2D plot of parameters. It can be seen from Fig. 2 that a set of limited parameters (diffusion, interface growth rate and grain-growth rate) explains our data best.

We obtained values of \({\dot G}\) ~ 10−11.0 m s–1, δDgb ~ 10−31.4 m3 s–1 and k ~ 10−39.5 m4.5 s–1 for P–T and \({\upvarepsilon}\) in our experiments that yield the least reduced chi-squared value.

Our model parameters obtained by inversion are close to and within experimental uncertainty of previous studies (Supplementary Table 1). Stress evolution using the best-fit values is plotted in Fig. 1. Our model not only explains our laboratory data but also can be used to extrapolate to Earth conditions, where diffusion creep, grain growth and phase transformation occur concurrently. Therefore, in the following, we use our model to discuss its application to Earth.

Application to Earth

In Earth, deformation takes place in a multicomponent system. As olivine is the volumetrically dominant mineral, it probably controls the rheological properties. In subducting slabs, olivine transforms directly to ringwoodite owing to sluggish olivine–wadsleyite transformation kinetics5,31. Therefore, we will focus on the deformation of olivine during phase transformation to ringwoodite.

Rheological properties of transforming materials are sensitive to the volume fraction and the geometry of new (weak) phase32. Mohiuddin and Karato7 showed that during a phase transformation, the new phase assumes a continuous film along grain boundaries and the film increases its thickness as transformation proceeds. Such microstructural evolution is similar to the interconnected weak layers (IWL) microstructure proposed by Handy19. In this case, one can assume a homogenous stress state and use the following equation to calculate the strain rate in the aggregate:

where \(\dot \varepsilon _{{\mathrm{aggregate}}}\) is the strain rate in the aggregate, \(\dot \varepsilon _{{\mathrm{olivine}}}\) is the strain rate in olivine, \(\dot \varepsilon _{{\mathrm{ringwoodite}}}\) is the strain rate in ringwoodite, V is the volume fraction of newly transformed ringwoodite and F(V) represents the evolution of strain partitioning from a stronger phase to a weaker phase. There is no well-accepted theory for F(V). However, F(V) must satisfy the following conditions: F(V) « 1 when V = 0 and F(V) = 1 when V = 1. We chose the following function, which satisfies the aforementioned criteria:

where β is the critical volume fraction above which the weaker phase controls deformation of the entire composite, and α determines the range of volume fraction over which strain is partitioned from the stronger to the weaker phase. Experimental studies on Ni–Al alloy18 and on partially molten granite32 suggest that the critical volume fraction required is 10, 20 and 30% (β = 0.1, 0.2, 0.3) and α ≈ 10.

Also from the results by van der Molen and Paterson32, we can place constraints on α and β, which govern the nature of strain-rate partitioning. It can be seen from fig. 14 in van der Molen and Paterson32 that strain-rate partitioning is sigmoidal in nature and takes place over a range of α = 100–200 and β = 0.2–0.3. Consequently, we assume that for deformation during phase transformation of olivine to ringwoodite, strain-rate partitioning evolution is sigmoidal in nature with relevant parameters of α = 10–200 and β = 0.1–0.3.

To estimate the strain rate generated in ringwoodite, we use equation (5) from our model; diffusion coefficient, grain-growth rate and interface growth rate are taken from Shimojuku et al.21, Yamazaki et al.22 and Mosenfelder et al.23, respectively. Strain rate in olivine is estimated for two different mechanisms: (1) dislocation creep (parameters are taken from Karato and Jung33 and Hirth and Kohlstedt34) and (2) the Peierls mechanism (parameters are taken from Kawazoe et al.35); our conclusion does not depend strongly on the choice of either of these deformation mechanisms in olivine. We make the following assumptions: (1) stress acting in slabs is 300 MPa (ref. 20), (2) typical velocity of a fast-subducting slab is 10 cm yr–1 (ref. 36), (3) pressure of a material at 410 km is taken as 14 GPa and increases with time according to the velocity of the slabs, (4) temperature profile in slabs is adiabatic (0.6 K km–1) (refs. 24,37), (5) temperature at 660 km in the coldest region of subducting slabs is assumed to be 900 K similar to the previous studies9,38 and (6) during the deformation of a two-phase mixture, rheological properties are described by equations (5), (7) and (8).

The results from the preceding calculation are plotted in Fig. 3. Volume fraction of transformed materials is ~25% at 550 km depth (Fig. 3a). The average grain size of olivine in mantle is ~5 mm. However, the average grain size of transformed materials is ~8 nm at ~350 km depth and increases to ~40 nm at 660 km depth (Fig. 3b) due to grain growth during phase transformation. When such large grain-size reduction takes place (in this case due to olivine–ringwoodite phase transformations), it can be seen from Fig. 3c that even the coldest (and hence strongest) region of a subducting slab deforms at a geologically noticeable strain rate (>10−15 s−1).

The parameters α and β used in these calculations are not well constrained at this time. However, for all plausible parameter space, the weakening occurs at the depth range of ~520–560 km that is not very sensitive to these parameters. This is because the volume fraction of newly formed ringwoodite increases rapidly with depth.

It is noted that these regions are made of a mixture of weak and strong materials that may lead to unstable deformation. Indeed, the depth range where two phases co-exist corresponds to the region of high deep earthquake activities26.

Data availability

All data associated with this study are in the body of the manuscript and its Supplementary Information.

References

Fukao, Y., Obayashi, M., Nakakuki, T. & Group, D. S. P. Stagnant slab: a review. Annu. Rev. Earth Planet. Sci. 37, 19–46 (2009).

Karato, S., Riedel, M. R. & Yuen, D. A. Rheological structure and deformation of subducted slabs in the mantle transition zone: implications for mantle circulation and deep earthquakes. Phys. Earth. Planet. 127, 83–108 (2001).

Ringwood, A. E. Phase transformations and their bearings on the constitution and dynamics of the mantle. Geochem. Cosmochem. Acta 55, 2083–2110 (1991).

Rubie, D. C. The olivine -> spinel transformation and the rheology of subducting lithosphere. Nature 308, 505–508 (1984).

Sung, C. M. & Burns, R. G. Kinetics of olivine-spinel transition—implications to deep-focus earthquake genesis. Earth Planet. Sci. Lett. 32, 165–170 (1976).

Rubie, D. C. & Ross, C. R. Kinetics of the olivine–spinel transformation in subducting lithosphere—experimental constraints and implications for deep slab processes. Phys. Earth Planet. 86, 223–241 (1994).

Mohiuddin, A. & Karato, S. An experimental study of grain-scale microstructure evolution during the olivine–wadsleyite phase transition under nominally “dry” conditions. Earth Planet. Sci. Lett. 501, 128–137 (2018).

Riedel, M. R. & Karato, S. Microstructural development during nucleation and growth. Geophys. J. Int. 125, 397–414 (1996).

Riedel, M. R. & Karato, S. Grain-size evolution in subducted oceanic lithosphere associated with the olivine–spinel transformation and its effects on rheology. Earth Planet. Sci. Lett. 148, 27–43 (1997).

Girard, J., Amulele, G., Farla, R., Mohiuddin, A. & Karato, S. Shear deformation of a bridgmanite–magnesiowüstite aggregate under the lower mantle conditions. Science 351, 144–147 (2016).

Nishihara, Y. et al. Plastic deformation of wadsleyite and olivine at high-pressure and high-temperature using a rotational Drickamer apparatus (RDA). Phys. Earth Planet. 170, 156–169 (2008).

Durham, W. B., Weidner, D. J., Karato, S. & Wang, Y. in Plastic Deformation of Minerals and Rocks (eds S. Karato & H.-R. Wenk) 21–49 (Mineralogical Society of America, 2002).

Yamazaki, D. & Karato, S. High pressure rotational deformation apparatus to 15 GPa. Rev. Sci. Instrum. 72, 4207–4211 (2001).

Karato, S. Theory of lattice strain in a material undergoing plastic deformation: basic formulation and applications to a cubic crystal. Phys. Rev. B 79, 214106 (2009).

Matsui, M. et al. The temperature–pressure–volume equation of state of platinum. J. Appl. Phys. 105, 013505 (2009).

Nishihara, Y. et al. Thermal equation of state of (Mg0.91Fe0.09)2SiO4 ringwoodite. Phys. Earth Planet. 143, 33–46 (2004).

Singh, A. K., Balasingh, C., Mao, H. K., Hemley, R. J. & Shu, J. F. Analysis of lattice strains measured under nonhydrostatic pressure. J. Appl. Phys. 83, 7567–7575 (1998).

Ponge, D. & Gottstein, G. Necklace formation during dynamic recrystallization: mechanisms and impact on flow behavior. Acta Mater. 46, 69–80 (1998).

Handy, M. R. Flow laws for rocks containing two nonlinear viscous phases—a phenomenological approach. J. Struct. Geol. 16, 1727–1727 (1994).

Bina, C. R. Phase transition buoyancy contributions to stresses in subducting lithosphere. Geophys. Res. Lett. 23, 3563–3566 (1996).

Shimojuku, A. et al. Si and O diffusion in (Mg,Fe)2SiO4 wadsleyite and ringwoodite and its implications for the rheology of the mantle transition zone. Earth Planet. Sci. Lett. 284, 103–112 (2009).

Yamazaki, D., Inoue, T., Okamoto, M. & Irifune, T. Grain growth kinetics of ringwoodite and its implication for rheology of the subducting slab. Earth Planet. Sci. Lett. 236, 871–881 (2005).

Mosenfelder, J. L., Marton, F. C., Ross, C. R., Kerschhofer, L. & Rubie, D. C. Experimental constraints on the depth of olivine metastability in subducting lithosphere. Phys. Earth Planet. 127, 165–180 (2001).

Karato, S.-i. Deformation of Earth Materials: An Introduction to the Rheology of Solid Earth (Cambridge Univ. Press, 2008).

Argon, A. S. in The Inhomogeneity of Plastic Deformation (ed R. E. Reed-Hill) 161–189 (American Society of Metals, 1973).

Green, H. W. Solving the paradox of deep earthquakes. Sci. Am. 271, 64–71 (1994).

Sinogeikin, S. V., Bass, J. D. & Katsura, T. Single-crystal elasticity of γ-(Mg0.91Fe0.09)2SiO4 to high pressures and to high temperatures. Geophys. Res. Lett. 28, 4335–4338 (2001).

Hustoft, J. et al. Plastic deformation experiments to high strain on mantle transition zone minerals wadsleyite and ringwoodite in the rotational Drickamer apparatus. Earth Planet. Sci. Lett. 361, 7–15 (2013).

Miyagi, L. et al. Plastic anisotropy and slip systems in ringwoodite deformed to high shear strain in the rotational Drickamer apparatus. Phys. Earth Planet. 228, 244–253 (2014).

Karato, S., Paterson, M. S. & Fitz Gerald, J. D. Rheology of synthetic olivine aggregates: influence of grain-size and water. J. Geophys. Res. 91, 8151–8176 (1986).

Sung, C. M. & Burns, R. G. Kinetics of high-pressure phase-transformations—implications to evolution of olivine–spinel transition in downgoing lithosphere and its consequences on dynamics of mantle. Tectonophysics 31, 1–32 (1976).

van der Molen, I. & Paterson, M. S. Experimental deformation of partially-melted granite. Contrib. Mineral. Petr. 70, 299–318 (1979).

Karato, S. & Jung, H. Effects of pressure on high-temperature dislocation creep in olivine polycrystals. Philos. Mag. 83, 401–414 (2003).

Hirth, G. & Kohlstedt, D. L. in Inside the Subduction Factory (ed J. E. Eiler) 83–105 (American Geophysical Union, 2003).

Kawazoe, T., Karato, S., Otsuka, K., Jing, Z. & Mookherjee, M. Shear deformation of dry polycrystalline olivine under deep upper mantle conditions using a rotational Drickamer apparatus (RDA). Phys. Earth Planet. 174, 128–137 (2009).

Gripp, A. E. & Gordon, R. G. Current plate velocities relative to the hotspots incorporating the nuvel-1 global plate motion model. Geophys. Res. Lett. 17, 1109–1112 (1990).

Hosoya, T., Kubo, T., Ohtani, E., Sano, A. & Funakoshi, K. Water controls the fields of metastable olivine in cold subducting slabs. Geophys. Res. Lett. 32, L17305 (2005).

Kubo, T., Kaneshima, S., Torii, Y. & Yoshioka, S. Seismological and experimental constraints on metastable phase transformations and rheology of the Mariana slab. Earth Planet. Sci. Lett. 287, 12–23 (2009).

Acknowledgements

We thank H. Chen from 6BM-B beamline at Argonne National Laboratory for her help with the experiments (proposal ID: 52991) that are partly supported by COMPRES. We also thank K. Kisslinger from the Center for Functional Nanomaterials at Brookhaven National Laboratory for his help with TEM sample preparation and imaging. We are also grateful to Z. Jiang for his help with SEM and to W. Samella and C. Fiederlein for helping with preparation of parts for rotational Drickamer apparatus cell assembly. This work was supported by National Science Foundation grant no. EAR-1445356.

Author information

Authors and Affiliations

Contributions

A.M. and S.-i.K. conceived the idea of the experiment, and A.M. and S.-i.K. wrote the manuscript. A.M. and J.G. conducted the experiments, and A.M. analysed the data.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Primary Handling Editors: Stefan Lachowycz; Melissa Plail.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary discussions, Figs. 1–11, Table 1 and references.

Rights and permissions

About this article

Cite this article

Mohiuddin, A., Karato, Si. & Girard, J. Slab weakening during the olivine to ringwoodite transition in the mantle. Nat. Geosci. 13, 170–174 (2020). https://doi.org/10.1038/s41561-019-0523-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41561-019-0523-3

This article is cited by

-

Resolving puzzles of the phase-transformation-based mechanism of the strong deep-focus earthquake

Nature Communications (2022)

-

Formation mechanisms of ringwoodite: clues from the Martian meteorite Northwest Africa 8705

Earth, Planets and Space (2021)

-

Dry metastable olivine and slab deformation in a wet subducting slab

Nature Geoscience (2021)