Abstract

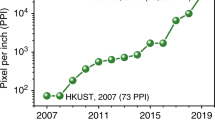

Micro-LEDs (µLEDs) have been explored for augmented and virtual reality display applications that require extremely high pixels per inch and luminance1,2. However, conventional manufacturing processes based on the lateral assembly of red, green and blue (RGB) µLEDs have limitations in enhancing pixel density3,4,5,6. Recent demonstrations of vertical µLED displays have attempted to address this issue by stacking freestanding RGB LED membranes and fabricating top-down7,8,9,10,11,12,13,14, but minimization of the lateral dimensions of stacked µLEDs has been difficult. Here we report full-colour, vertically stacked µLEDs that achieve, to our knowledge, the highest array density (5,100 pixels per inch) and the smallest size (4 µm) reported to date. This is enabled by a two-dimensional materials-based layer transfer technique15,16,17,18 that allows the growth of RGB LEDs of near-submicron thickness on two-dimensional material-coated substrates via remote or van der Waals epitaxy, mechanical release and stacking of LEDs, followed by top-down fabrication. The smallest-ever stack height of around 9 µm is the key enabler for record high µLED array density. We also demonstrate vertical integration of blue µLEDs with silicon membrane transistors for active matrix operation. These results establish routes to creating full-colour µLED displays for augmented and virtual reality, while also offering a generalizable platform for broader classes of three-dimensional integrated devices.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

All data generated or analysed during this study are included in the paper.

References

Lee, V. W., Twu, N. & Kymissis, I. Micro-LED technologies and applications. Inf. Disp. 32, 16–23 (2016).

Zhan, T., Yin, K., Xiong, J., He, Z. & Wu, S.-T. Augmented reality and virtual reality displays: perspectives and challenges. iScience 23, 101397 (2020).

Gong, Z. Layer-scale and chip-scale transfer techniques for functional devices and systems: a review. Nanomaterials (Basel) 11, 842 (2021).

Wu, Y., Ma, J., Su, P., Zhang, L. & Xia, B. Full-color realization of micro-LED displays. Nanomaterials (Basel) 10, 2482 (2020).

Marinov, V. R. 52-4: Laser-enabled extremely-high rate technology for µLED assembly. SID Symp. Dig. Tech. Pap. 49, 692–695 (2018).

Bower, C. A. et al. Emissive displays with transfer-printed assemblies of 8 µm x 15 µm inorganic light-emitting diodes. Photon. Res. 5, A23–A29 (2017).

Chun, J. et al. Vertically stacked color tunable light-emitting diodes fabricated using wafer bonding and transfer printing. ACS Appl. Mater. Interfaces 6, 19482–19487 (2014).

Kang, C.-M. et al. Monolithic integration of AlGaInP-based red and InGaN-based green LEDs via adhesive bonding for multicolor emission. Sci. Rep. 7, 10333 (2017).

Kang, C.-M. et al. Hybrid full-color inorganic light-emitting diodes integrated on a single wafer using selective area growth and adhesive bonding. ACS Photonics 5, 4413–4422 (2018).

Jin, H. et al. Vertically stacked RGB LEDs with optimized distributed Bragg reflectors. Opt. Lett. 45, 6671–6674 (2020).

Li, L. et al. Transfer-printed, tandem microscale light-emitting diodes for full-color displays. Proc. Natl Acad. Sci. USA 118, e2023436118 (2021).

Mun, S.-H. et al. Highly efficient full-color inorganic LEDs on a single wafer by using multiple adhesive bonding. Adv. Mater. Interfaces 8, 2100300 (2021).

El-Ghoroury, H. S., Chuang, C.-L. & Alpaslan, Z. Y. 26.1: Invited paper: quantum photonic imager (QPI): a novel display technology that enables more than 3D applications. SID Symp. Dig. Tech. Pap. 46, 371–374 (2015).

Yadavalli, K., Chuang, C.-L. & El-Ghoroury, H. Monolithic and heterogeneous integration of RGB micro-LED arrays with pixel-level optics array and CMOS image processor to enable small form-factor display applications. In Proc. SPIE 11310, Optical Architectures for Displays and Sensing in Augmented, Virtual, and Mixed Reality (AR, VR, MR) (eds Kress, B. C. & Peroz, C.) 113100Z (SPIE, 2020).

Ayari, T. et al. Wafer-scale controlled exfoliation of metal organic vapor phase epitaxy grown InGaN/GaN multi quantum well structures using low-tack two-dimensional layered h-BN. Appl. Phys. Lett. 108, 171106 (2016).

Li, X. et al. Large-area two-dimensional layered hexagonal boron nitride grown on sapphire by metalorganic vapor phase epitaxy. Crystal Growth Des. 16, 3409–3415 (2016).

Kim, Y. et al. Remote epitaxy through graphene enables two-dimensional material-based layer transfer. Nature 544, 340–343 (2017).

Kim, H. et al. Impact of 2D–3D heterointerface on remote epitaxial interaction through graphene. ACS Nano 15, 10587–10596 (2021).

Kim, H.-s et al. Unusual strategies for using indium gallium nitride grown on silicon (111) for solid-state lighting. Proc. Natl Acad. Sci. USA 108, 10072–10077 (2011).

Kim, T.-i et al. High-efficiency, microscale GaN light-emitting diodes and their thermal properties on unusual substrates. Small 8, 1643–1649 (2012).

LaValle, S. M. Virtual Reality (Cambridge Univ. Press, 2016).

Kum, H. et al. Epitaxial growth and layer-transfer techniques for heterogeneous integration of materials for electronic and photonic devices. Nat. Electron. 2, 439–450 (2019).

Cheng, J.-H., Wu, Y. S., Peng, W. C. & Ouyang, H. Effects of laser sources on damage mechanisms and reverse-bias leakages of laser lift-off GaN-based LEDs. J. Electrochem. Soc. 156, H640 (2009).

Jiang, J. et al. Carrier lifetime enhancement in halide perovskite via remote epitaxy. Nat. Commun. 10, 4145 (2019).

Journot, T. et al. Remote epitaxy using graphene enables growth of stress-free GaN. Nanotechnology 30, 505603 (2019).

Bae, S.-H. et al. Graphene-assisted spontaneous relaxation towards dislocation-free heteroepitaxy. Nat. Nanotechnol. 15, 272–276 (2020).

Chang, H. et al. Graphene-driving strain engineering to enable strain-free epitaxy of AlN film for deep ultraviolet light-emitting diode. Light Sci. Appl. 11, 88 (2022).

Chen, Z. et al. Improved epitaxy of AlN film for deep-ultraviolet light-emitting diodes enabled by graphene. Adv. Mater. 31, 1807345 (2019).

Ryou, J. et al. Control of quantum-confined Stark effect in InGaN-based quantum wells. IEEE J. Sel. Top. Quantum Electron. 15, 1080–1091 (2009).

Chen, J. & Packard, C. E. Controlled spalling-based mechanical substrate exfoliation for III-V solar cells: a review. Sol. Energy Mater. Sol. Cells 225, 111018 (2021).

Zhang, B., Luo, C. & Li, Y.-F. Damage-free transfer of GaN-based light-emitting devices and reuse of sapphire substrate. ECS J. Solid State Sci. Technol. 9, 065019 (2020).

Bauhuis, G. J. et al. Wafer reuse for repeated growth of III–V solar cells. Prog. Photovolt. 18, 155–159 (2010).

Kim, H. et al. Multiplication of freestanding semiconductor membranes from a single wafer by advanced remote epitaxy. Preprint at https://arxiv.org/abs/2204.08002 (2022).

Day, J. et al. III-nitride full-scale high-resolution microdisplays. Appl. Phys. Lett. 99, 031116 (2011).

Meng, W. et al. Three-dimensional monolithic micro-LED display driven by atomically thin transistor matrix. Nat. Nanotechnol. 16, 1231–1236 (2021).

Ludovic, D. et al. Processing and characterization of high resolution GaN/InGaN LED arrays at 10 micron pitch for micro display applications. In Proc. SPIE 10104, Gallium Nitride Materials and Devices XII (eds Chyi, J.-I. et al.) 1010422 (SPIE, 2017).

Chen, G.-S., Wei, B.-Y., Lee, C.-T. & Lee, H. Y. Monolithic red/green/blue micro-LEDs with HBR and DBR structures. IEEE Photonics Technol. Lett. 30, 262–265 (2018).

Park, J. et al. Electrically driven mid-submicrometre pixelation of InGaN micro-light-emitting diode displays for augmented-reality glasses. Nat. Photon. 15, 449–455 (2021).

Carlson, A., Bowen, A. M., Huang, Y., Nuzzo, R. G. & Rogers, J. A. Transfer printing techniques for materials assembly and micro/nanodevice fabrication. Adv. Mater. 24, 5284–5318 (2012).

Forrest, S. R., Bradley, D. D. C. & Thompson, M. E. Measuring the efficiency of organic light-emitting devices. Adv. Mater. 15, 1043–1048 (2003).

Acknowledgements

The team at Massachusetts Institute of Technology (MIT) acknowledges support from the National Science Foundation (award no. 2001231), the Defense Advanced Research Projects Agency Young Faculty Award (no. 029584-00001), the Air Force Research Laboratory (award no. FA9453-21-C-0717) and the US Department of Energy’s Office of Energy Efficiency and Renewable Energy under the Solar Energy Technologies Office (award no. DE-EE0008558). The team at MIT also acknowledges support, in part, by LG electronics and Rohm Semiconductor. The team at Georgia Tech-Lorraine acknowledges partial funding by the French National Research Agency under the GANEXT Laboratory of Excellence project. The work by Y.J.H., J.J. and J.C. was supported by a National Research Foundation of Korea grant funded by the Ministry of Science and ICT (nos. 2018K1A4A3A01064272, NRF-2021R1A5A1032996 and 2022M3D1A2050793) and by the Ministry of Education (no. 2022R1A6C101A774).

Author information

Authors and Affiliations

Contributions

Jeehwan Kim, A.O., Y.J.H., K.C. and K. Lee conceived the idea and directed the team. J.S. coordinated and designed the experiments and characterization. H.K., S.S., J.J., B.-I.P., J.C. and K. Lu developed and performed epitaxial growth of red, blue and green LED films under the guidance of Jeehwan Kim, A.O. and Y.J.H. 2D material-coated substrates were prepared by H.K., S.S., J.J., B.-I.P., K. Lu, Y.L., K.Q. and Jekyung Kim. T.K. developed Si TFTs under the guidance of K.J.Y. M.S. developed the set-up and codes for measurement of luminance, EQE and radiation pattern under the guidance of V.B., and J.S., J.J., M.S. and J.H.K. collected the data. J.S., H.K., J.J., M.-K.S., K. Lu, S.K., J.L., J.M.S., J.-H.K., J.S.K. and D.L. carried out layer transfer and fabrication of LEDs. J.S. collected I–V curves, EL microscopy images and optical transmission spectra. H.K., S.S. and K. Lu performed EBSD and XRD analyses. XPS and AFM data were collected by K.S.K. EL spectra were obtained by J.S. and H.K. All SEM, EDX and STEM imaging and analyses were performed by C.S.C. J.M.S. designed all three-dimensional schematic illustrations. H.E.L., H.Y., Y.K., H.S.K., S.-H.B. and K. Lee provided feedback throughout experiments and data analysis. The manuscript was written by J.S., H.K., S.S., J.J., Y.J.H., A.O. and Jeehwan Kim. All authors contributed to the analysis and discussion of results leading to the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature thanks Kazuhiro Ohkawa and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

Extended Data Fig. 1 Schematic illustrations of the 2D material-based layer transfer and vertical heterointegration process for constructing full-color vertical µLEDs.

The layers are transferred and stacked in the order of red, green, and blue LEDs using polyimide as adhesion layer.

Extended Data Fig. 2 XRD, EBSD, and AFM measurements of ultrathin RGB LED films obtained via 2DLT.

a-c, XRD 2θ-ω scan results for red (a), green (b), and blue (c) LED films. d-f, XRD Φ scan results for red (d), green (e), and blue (f) LED films. g-i, EBSD analysis results for red (g), green (h), and blue (i) LED films. j-l, AFM morphology images for red (j), green (k), and blue (l) LED films.

Extended Data Fig. 3 Luminance and external quantum efficiencies (EQEs) of RGB µLEDs.

a-d, Measured luminance of red (a), green (b), blue (c), and reference (d) µLEDs of varying size. e-h, Measured EQEs of red (e), green (f), blue (g), and reference (h) µLEDs of varying size. Red, green, and blue µLEDs are obtained via 2DLT, while reference devices are blue µLEDs grown directly on sapphire substrate without 2D layer.

Extended Data Fig. 4 Verification of reusability of sapphire substrates after 2DLT.

a-b, XPS spectra of B 1s (a) and N 1s (b) regions for hBN-coated sapphire wafer (reference; black), used sapphire wafer following exfoliation of LED (LED exfol.; blue), and used sapphire wafer after removal of residual hBN layer (hBN removal; red). c-d, SEM images of blue LEDs on hBN grown on pristine (d) and reused (e) sapphire wafers.

Extended Data Fig. 5 Optimization of optical transmission characteristics of absorber interlayers.

a-e, Optical transmission spectra obtained from absorber layers with varying concentrations of dyes dissolved in the PI precursor (a), film curing temperatures (b), types of dye product (c), film thickness (represented as spin-coating rate) (d), and types of PI (colorless PI from Kolon, Inc. and PI-2545 from HD Microsystems, Inc.) (e). Parameters in parentheses represent conditions that apply for all data in each plot. (a, Insets) Photographs of representative absorber layers coated on glass slide.

Extended Data Fig. 6 Si TFTs on silicon-on-insulator wafer.

a, b, Optical microscopy images of a 30 × 30 array of silicon TFTs fabricated on silicon-on-insulator wafer. Each TFT has dimensions of 2.2 μm × 9.2 μm. c, Transfer characteristics of the silicon TFT with W/L of 1.5 μm/2.2 μm, driven at VDS of 2 V. d, Output characteristics of a Si TFT showing current saturation at VGS values ranging from 0.5 V to 2.5 V.

Extended Data Fig. 7 Si TFT-integrated blue InGaN μLEDs.

a, b, Optical microscopy and tilted SEM images of a 30 × 30 array of blue μLEDs vertically integrated with silicon TFTs. c, Cross-sectional SEM image of a blue μLED transferred on a 300 nm-thick silicon TFT on silicon-on-insulator wafer by PI adhesive layer and electrically interconnected by sputtered metal. d, Optical images of the active matrix μLED display displaying the ‘mit’ logo. Scale bar, 200 μm.

Extended Data Fig. 8 Schematic illustrations and optical microscope images of 2DLT-based, selective µLED mass transfer process for manufacturing large-scale displays.

The process involves the fabrication of blue LED chips (size ~10 µm) on hBN-coated sapphire substrate (step i), photolithography of a partially-developed photoresist (PR) pattern that exposes only the upper bodies of µLEDs to be transferred (step ii), deposition of Ni stressor layer and attachment of handling tapes (step iii), and mechanical lift-off of the exposed µLEDs via cleavage through the hBN layer (steps iv), which leaves behind the PR-coated chips on sapphire substrate that can undergo cleaning and additional lift-off (step ii). The slippery surface of 2D materials, combined with photolithography-based selection approach, enables facile yet highly resolved extraction of µLED chips among a densely-packed array (chip-to-chip separation ~10 µm). Cleaning the PR residue, transferring the µLEDs onto a secondary substrate, and removing Ni and underlying PI layers complete the process (steps v-vii).

Extended Data Fig. 9 Blue LED grown via remote epitaxy on GaN wafer.

a, Schematic illustrations of the epitaxial structures of InGaN-based blue LED grown on GaN wafer. b, AFM morphology image of a GaN film grown via remote epitaxy. c, SEM images of the surfaces of GaN films grown via remote (left) and van der Waals (right) epitaxy techniques. d-e, Measured EQEs and luminance of blue µLEDs of varying size grown on GaN substrate.

Supplementary information

Supplementary Information

Supplementary Notes 1–6, Figs. 1–11 and Table 1.

Supplementary Video 1 Exfoliation of blue LED film from hBN-sapphire wafer.

Video recordings of the exfoliation process for 2-inch-wafer-sized blue LED membrane, highlighting the high speed and yield.

Supplementary Video 2 Electroluminescence of mixed colours for vertical micro-LEDs.

Video recordings of the emission of various mixed colours by vertical µLEDs.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Shin, J., Kim, H., Sundaram, S. et al. Vertical full-colour micro-LEDs via 2D materials-based layer transfer. Nature 614, 81–87 (2023). https://doi.org/10.1038/s41586-022-05612-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-022-05612-1

This article is cited by

-

The Roadmap of 2D Materials and Devices Toward Chips

Nano-Micro Letters (2024)

-

Waveguide-based augmented reality displays: perspectives and challenges

eLight (2023)

-

Unveiling the mechanism of remote epitaxy of crystalline semiconductors on 2D materials-coated substrates

Nano Convergence (2023)

-

Applications of remote epitaxy and van der Waals epitaxy

Nano Convergence (2023)

-

Lattice modulation strategies for 2D material assisted epitaxial growth

Nano Convergence (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.