Abstract

Polymer hydrogels are promising materials for various applications due to their unique properties. The precise construction of networked structures is required for the development of gel materials with improved functionality. This focus review outlines the structural design of polymer gels by utilizing precision radical polymerization techniques, mainly focusing on the authors’ recent research. First, the anticipated advantages of precision radical polymerization in gel synthesis are briefly explained. Then, our approach to synthesizing gels with a homogeneous network structure is described. Finally, controlling the swelling behavior of gels prepared from two types of monomers is highlighted with a focus on the regulation of the monomer sequence in the network chains.

Similar content being viewed by others

Introduction

Polymer hydrogels consist of a three-dimensional polymer network with water molecules within the structure (Fig. 1). This structural feature gives hydrogels soft and wet characteristics by combining solid-like properties derived from the polymer chains and liquid-like properties from the water. Because of these unique properties, hydrogels have been used for years and are considered environmentally friendly materials for various applications [1,2,3,4,5,6,7].

Hydrogels generally possess good flexibility, low surface friction, and desirable substance retention and permeability. In addition to these advantages, various functionalities can be imparted into the gels by selecting the appropriate polymer network chains. In particular, since the volume phase transition behavior of poly(acrylamide derivative) gels was discovered by Tanaka et al. [8], hydrogels have attracted much attention as smart materials that autonomously change their properties in response to external stimuli. One representative example is the thermoresponsive poly(N-isopropylacrylamide) (PNIPAAm) gel, which reversibly swells and shrinks at ~32 °C in pure water [9,10,11]. Vinyl compounds, which possess a carbon–carbon double bond, such as NIPAAm, are useful precursors for gels because of their structural diversity, and vinyl polymer gels are generally synthesized by free radical polymerization of vinyl monomers in the presence of a cross-linking agent bearing two vinyl groups, such as N,N′-methylenebisacrylamide (MBAAm). This preparation method is simple and easy, and therefore vinyl hydrogels are commonly used materials. However, it is impossible to control the network structure due to the concurrent and random propagation and cross-linking reactions (Fig. 1). The spatial distribution of cross-linking points is inhomogeneous, and the network involves unreacted vinyl groups derived from the cross-linker and dangling chains that do not contribute to the network structure [12,13,14]. In addition, the monomer sequence is also difficult to control when two or more kinds of monomers are copolymerized to tune the gel properties. Such uncontrollable structural factors often greatly influence the gel properties. In other words, to enhance the gel function, precise control of the network structure of the hydrogels is important. Thus, we are focusing on the utilization of a precision radical polymerization technique for the design of cross-linked structures and functionalization of hydrogels based on the control of the monomer sequence along the network chains. This focus review starts with a brief description of the advantages of precision radical polymerization in gel synthesis and outlines our recent results in two main fields: the design of cross-linked structures and functionalization by controlling the monomer sequence in network chains.

Precision radical polymerization and sequence control in gel synthesis

Precision radical polymerization techniques have advanced remarkably in recent decades due to the development of novel catalysts and reaction mechanisms [15,16,17,18,19,20,21]. The important feature for controlled polymerization is the regulation of propagation reactions by reversible activation of the growing end (therefore, this method has recently been called “reversible deactivation radical polymerization”). By using such controlled polymerization, it is becoming possible to control the molecular weight and achieve narrow molecular weight distributions for various polymers. In addition, block copolymers with two or more kinds of monomers and polymers with unique topology, such as graft and star polymers, can also be obtained.

One of the advantages of using such a precision radical polymerization technique for gel synthesis is the utilization of polymers with defined structures as precursors for network formation. Here, it is also important to use a highly efficient reaction, such as “click chemistry” [22], for cross-linking to obtain the designed network. The combination of precision radical polymerization and click chemistry is a powerful tool not only for controlling the spatial distribution of cross-linking points but also for designing amphiphilic conetwork structures using block copolymers. Recent examples are discussed in the next sections.

Design of a homogeneous network

The first advantage of precision radical polymerization in gel synthesis is the design of a homogeneous network structure with a uniform molecular weight between the cross-linking points. A gel with a nonuniform network easily breaks on a macro scale due to stress concentration in network chains with low-molecular weight. Since this is directly related to the low mechanical strength of gel materials, the realization of a homogeneous network is desirable. In addition, the synthesis of a uniform network structure is considered to be the basis for the design of various gel network structures. Furthermore, obtaining such a designed network helps us theoretically understand the details of the gel properties, such as the swelling and mechanical properties. Based on these backgrounds, many studies on the synthesis of homogeneous networks have been conducted [23]. The typical synthetic method involves linking the end groups of controlled polymers with a uniform molecular weight.

One of the most successful examples in recent years is a tetra-poly(ethylene glycol) (tetra-PEG) gel reported by Sakai et al. [24]. The tetra-PEG gel is prepared by the cross reaction of two types of 4-arm star PEGs having mutually reactive terminal groups synthesized by living anionic ring-opening polymerization. These polymeric precursors have equal molecular weights with narrow molecular weight distributions and react with each other at their termini to produce highly homogeneous structures. By using this tetra-PEG gel, it is becoming possible to discuss the correlation between the theoretical and experimental physical properties of gels in detail [25,26,27,28]. On the other hand, from the viewpoint of structural diversity, the incorporation of various functional groups into PEG-based polymers is difficult, and the preparation of a homogeneous network using various functionalized vinyl monomers is still required.

The recent development of precision radical polymerization would dramatically advance the network design of polymer gels. In particular, the combination of highly efficient reactions with a high tolerance for various functional groups is a promising approach for preparing homogeneous networks. There are two typical methods. One is the reaction of controlled telechelic polymers having reactive sites at both termini with a branched, low-molecular-weight cross-linker [29,30,31,32]. In this method, the synthesis of telechelic polymers is relatively simple using a precision radical polymerization technique, but the reaction can be affected by steric hindrance from the polymers during the cross-linking reaction. The other method utilizes four-armed star-shaped polymers as same as the synthesis of tetra-PEG gel [33,34,35,36]. For example, Oshima et al. reported the synthesis of poly(sodium acrylate) gel by this scheme [33]. They synthesized two kinds of four-branched poly(t-butyl acrylates) with azide and alkyne termini by a copper-catalyzed atom transfer radical polymerization (ATRP), and cross-linked them by a copper-catalyzed azide-alkyne cycloaddition (CuAAC) followed by deprotection of the t-butyl groups for the gel synthesis. The obtained gel showed improved mechanical properties due to its more homogeneous structure relative to that of the conventional gel prepared by divinyl cross-linking. Although this system using four-armed star polymers is promising, it requires the preparation of a branched multifunctional initiator, and more importantly, it should proceed via a uniform initiation and propagation reaction from each initiating site with maintaining its reactivity throughout the polymerization, which further complicated the reaction. In fact, in the system of Oshima et al., the polymerization was quenched in the early stage (the monomer conversion was ~20%) to avoid end-deactivation. The combination of ATRP and CuAAC is regarded as an advantageous system because both reactions proceed with the same copper catalytic system, and the polymer terminal groups obtained by ATRP are easily converted into azide groups. However, the copper catalyst should be removed after the gel synthesis prior to applications, and this purification is sometimes problematic depending on the structure of the network chains.

Thus, gel synthesis by the end-linking of controlled polymeric precursors as described above is promising for the regulation of network structures with uniform molecular weights between the cross-linking points. Furthermore, Satoh and Takeoka et al. recently reported a novel one-pot preparation method combining a multifunctional initiator and a core-cross-linked star polymer synthesis by ATRP [37]. The exploration of such new reaction systems is also important.

Design of a homogeneous network by utilizing RAFT polymerization

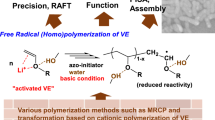

Among the various precision radical polymerization techniques, we are focusing on reversible addition-fragmentation chain-transfer (RAFT) polymerization for gel synthesis. RAFT polymerization is a metal-free system using a thiocarbonylthio (-C(=S)-S-) compound called a RAFT agent, and the polymerization is controlled through rapid and reversible addition/fragmentation reactions between the growing radical chain and the polymeric RAFT agents, as shown in Fig. 2 [15,16,17]. This RAFT polymerization can be carried out by simply adding a RAFT agent to a conventional free radical polymerization system, and it is suitable for diverse functional monomers, including acrylamide derivatives such as NIPAAm. Furthermore, a symmetric trithiocarbonate (-SC(=S)-S-: TTC) compound can afford a telechelic polymer with a TTC group at the center of the polymer chain. Such TTC compounds can initiate RAFT polymerizations upon UV irradiation [38, 39], and Matyjaszewski et al. reported that a network polymer with built-in TTC moieties showed self-healing properties [40, 41].

Based on these features, we proposed a synthetic strategy for preparing a homogeneous network with self-healing properties to achieve excellent mechanical properties and material durability by utilizing a TTC-mediated RAFT polymerization (Fig. 3) [42]. We synthesized a telechelic PNIPAAm with succinimide ester groups, which are known as “activated esters” with high reactivity to amine compounds, at both termini by RAFT polymerization using a symmetrical TTC RAFT agent (CTA1) and end-group esterification. The obtained prepolymer had a TTC moiety in the center of the molecule, and it was cross-linked by the reaction with a three-armed amine cross-linker. The optimization of the reaction conditions led to the successful synthesis of a chemically stable gel, but the cross-linking reaction efficiency was low, and the obtained gel was far from homogeneous. However, the obtained gels did exhibit UV-induced self-healing due to the presence of TTC groups located in the center of the network chains. These results indicated that the RAFT polymerization mechanism had a substantial impact not only in the construction of the structural components but also in the properties of the gel materials. The cross-linking efficiency requires improvement, but this strategy could facilitate the design of materials with high strength and durability. In particular, this end-cross-linking system using a symmetric RAFT agent can be applied to a variety of monomers because of the functional group tolerance of RAFT polymerization. This approach can afford various self-healable cross-linked polymer materials, such as hydrogels including PNIPAAm gel as well as organogels and elastomers without unique molecular features.

To improve the cross-linking efficiency in this end-cross-linking system, the appropriate selection of the cross-linking reaction and optimization of the reaction conditions are important. To this end, we then examined the thiol-ene reaction as a cross-linking reaction of telechelic polymers [43]. The thiol-ene reaction is useful for end-cross-linking systems in combination with RAFT polymerization, because this reaction is regarded as a typical click reaction with high efficiency and reactivity, and the end structure of the polymer derived from the RAFT agent can easily be converted into a thiol group by aminolysis [22, 44]. We synthesized telechelic PNIPAAm with thiol groups at both termini by RAFT polymerization using a symmetrical and bifunctional RAFT agent with two TTC groups (CTA2) followed by aminolysis (Fig. 4). Then, the gel synthesis was examined by reacting the obtained polymer with a four-armed acrylate cross-linker with azobisisobutyronitrile (AIBN) as a radical source in various solvents. The results revealed that the polarity of the reaction solvent strongly affected the molecular weight of the product, and in particular, alcoholic solvents gave stable gels. This result suggests that the expansion of the telechelic polymer in the reaction media is important in the network formation by end-cross-linking systems, which contributes to establishing design criteria for homogeneous networks. We regard controlled telechelic prepolymers prepared by RAFT polymerization as useful building blocks for the preparation of functional gel materials with homogeneous networks, and further investigations toward improving the cross-linking efficiency are being conducted.

Thermoresponsiveness expressed by copolymerization

PNIPAAm gel is a representative thermoresponsive gel that shows a reversible volume change at ~32 °C in pure water. This thermoresponsiveness is attributed to an adequate balance between hydrophilicity and hydrophobicity in the chemical structure of the monomer. The effect of the hydration of the hydrophilic amide group induces swelling of the PNIPAAm gel at low temperature, whereas increasing the temperature leads to dehydration, and simultaneously, the effect of the hydrophobic aggregation of the isopropyl group becomes dominant, causing macroscopic shrinkage of the gel (Fig. 5a). Inspired by this PNIPAAm structure with hydrophilic and hydrophobic sites coexisting in the monomeric unit, we have considered the design of thermoresponsive gels by combining a hydrophilic monomer with a hydrophobic monomer, neither of which shows thermoresponsiveness alone, to maintain an appropriate balance of hydrophilicity and hydrophobicity in the overall network. Such thermoresponsiveness achieved by combining “nonthermoresponsive” monomers has been reported in some cases for linear polymers [45,46,47,48], but to the best of our knowledge, there have been no detailed reports on such properties in polymer gels. Since thermoresponsive polymer gels showing macroscopic volume changes are considered to behave differently from linear polymers and are anticipated to have various applications, fundamental analysis and clarification of their swelling behavior is important. Furthermore, the achievement of responsiveness by combining common monomers would remarkably expand the possibilities for designing thermoresponsive materials with a variety of responsive behaviors, including the tuning of temperature and sharpness of the responsiveness, compared with what can be achieved with a gel from a single monomer.

Based on these backgrounds, we are investigating a variety of combinations of hydrophilic and hydrophobic monomers. A typical example is the copolymerization gel of hydrophilic N,N-dimethylacrylamide (DMAAm) and hydrophobic N-n-butylacrylamide (NBAAm) prepared by radical copolymerization in the presence of MBAAm [49]. This gel changed in volume in response to temperature changes as the proportion of hydrophobic monomers increased (Fig. 5b). Particularly, when the ratio of the two monomers is close to 1:1, the response behavior of the gel was relatively sharp, occurring in a small temperature range, such as that seen with PNIPAAm gel. Furthermore, when hydrophobic monomers were altered from NBAAm to isomeric monomers with different butyl groups (iso-butyl, sec-butyl, and tert-butyl acrylamides), the copolymerization gels with DMAAm also exhibited thermoresponsive behavior, but the behaviors were different depending on the butyl structure, even at the same composition ratio. This indicates the possibility of fine-tuning of the thermoresponsive swelling behavior of polymer gels by slight structural changes to common monomers. Since the reactivities of these monomers in these combinations in the copolymerization are similar, an alternating sequence of the two monomers tends to form during the gelation reaction when the feed ratio of the monomers is close to 1:1. This hydrophilic/hydrophobic alternating structure can be regarded as a local amphiphilic structure similar to the monomer structure of NIPAAm, which is supposed to play an important role in its thermoresponsive properties. This highlights the importance of the monomer sequence in network chains on the swelling behavior, and we are further investigating various monomer combinations to clarify the correlation between the monomer sequence and the swelling behavior of polymer gels in more detail. We also expect that the new design criteria for preparing thermoresponsive polymer gels with various responsive behaviors from a combination of common monomers could be obtained.

Effect of the monomer sequence in the network chains on gel properties

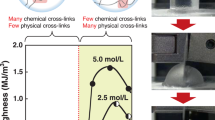

The properties of random copolymers and block copolymers are completely different even with the same composition. Similarly, it is necessary to consider the effect of the sequence of monomers in network chains on the properties of gels possessing two or more types of monomers even in the same composition. To this end, we expanded the aforementioned DMAAm/NBAAm combination for the construction of block-type sequence and examined the difference in swelling behavior with that of a random sequence [50]. The gels with block-type sequences were prepared by post-polymerization cross-linking of two kinds of prepolymers (PDMAAm and PNBAAm synthesized by free radical polymerization: Mn = 44,000 ~ 54,000; Mw/Mn = 1.7 ~ 1.8 determined by size-exclusion chromatography with poly(methyl methacrylate) calibration) having activated ester groups with a diamine cross-linker. We call this synthetic method “co-cross-linking” in contrast to the copolymerization method. Comparing the network structures, each network chain consists of a random sequence of the two monomers in a copolymerization gel, whereas with co-cross-linking, the gel is formed with two kinds of homopolymers, as shown in Fig. 6a. In the combination of DMAAm and NBAAm, the copolymerization gel swelled in water at low temperature even when the content of the hydrophobic component reached 50%, and it shrank as the temperature increased, as mentioned above. On the other hand, the incorporation of only 10% of the hydrophobic component in the co-cross-linking gel resulted in shrinking and white turbidity at low temperatures, such as 5 °C (Fig. 6b).

We also investigated the effect of the monomer sequence on the thermoresponsive behavior of PNIPAAm gels combined with hydrophobic NBAAm or hydrophilic DMAAm. These copolymerized gels were also prepared by free radical copolymerizations in the presence of MBAAm, and the co-cross-linked gels were synthesized with PNIPAAm prepolymer prepared by free radical polymerization (Mn = 77,000; Mw/Mn ~ 1.5) and the aforementioned PDMAAm or PNBAAm prepolymers. As a result, the response temperature of the copolymerized gels with a random network tended to shift according to the monomer composition. That is, the incorporation of NBAAm units into the network pushed the response temperature downward, while increasing the DMAAm content resulted in a higher response temperature (Fig. 7a). In contrast, the co-cross-linked gels with block-type sequences showed only a slight change in response temperature, but the degree of swelling was strongly influenced by the monomer composition (Fig. 7b). Thus, the effect of the monomer sequence on the swelling properties of poly(acrylamide derivative) gels was clarified. Here, it should be noted that such a trend in the swelling behavior would be affected by the molecular weight of the network chains. In particular, polymer chains with lower molecular weights induce different behaviors in block-type networks even with the same composition. Now, we are trying to further elucidate the correlation between the monomer sequence along the network chains and the gel properties by controlling the molecular weight of the network chains and expanding the monomer species.

Design of cross-linked domain structures in amphiphilic conetworks

Gels composed of two kinds of polymers, such as co-cross-linked gel, are generally called amphiphilic polymer networks or amphiphilic conetworks (APCNs) [51, 52]. APCNs with appropriately designed structures show unique characteristics reflecting the properties of the two constituent polymer chains. For example, some APCNs with independent hydrophilic and hydrophobic chains are swellable both in water and organic solvents [53,54,55,56,57,58]. Stimuli-responsive chains are also attractive components for APCNs, and APCNs showing unique responses, such as rapid shrinking and mechanical toughening, have been reported [59,60,61,62,63,64].

To effectively utilize the structural features of such APCNs, the careful control of the spatial arrangement of the two kinds of polymers in the network is required. In addition to this requirement, we emphasize the importance of the spatial distribution of the cross-linking points in the APCNs because the cross-linking points are the most important feature of polymer gels departing from linear polymers. Along this line, we proposed a novel design for APCNs involving the incorporation of cross-linking points into only one part of the two polymer chains constituting the APCNs (Fig. 8) [65]. This structure consists of cross-linked polymer domains (CDs) dispersed in the network and polymer chains bridging the CDs; therefore, the two kinds of polymer chains are distinctly compartmentalized in the network. This structural feature results in the effective incorporation of the functionalities of both polymer chains. Moreover, a polymer chain in a CD and a bridging chain differ in mobility due to the presence or absence of cross-links, which may affect the stimuli-responsive behavior depending on the sequence in the network. Such a hierarchical structure would contribute to the development of novel materials, for example sensing materials that can change stepwise in response to multiple stimuli, and a carrier holding multiple substances in different domains and changing release properties depending on the substance.

Toward the design of such APCNs, we utilized a triblock prepolymer with reactive sites only in the outer blocks. The prepolymers with inverted monomer sequences, thermoresponsive/hydrophilic/thermoresponsive and hydrophilic/thermoresponsive/hydrophilic domains, were prepared by RAFT block polymerization of NIPAAm and DMAAm using CTA2. Then, these prepolymers were cross-linked by reacting the embedded activated ester groups with a diamine cross-linker. The obtained gels are considered to form CD structures derived from the outer blocks of the triblock prepolymers. These designed gels with CD structures swelled in water at low temperatures to a much greater extent than a randomly cross-linked gel because of the CD structure, which possesses concentrated cross-linking points. In addition, these gels shrank dramatically in a narrow window in response to temperature changes due to the effective function of the thermoresponsive polymer chains. Furthermore, this shrinkage is faster than that of the gel with a random monomer/cross-linker sequence because the hydrophilic domains inside the network allowed the water to efficiently exit the gel upon dehydration. Interestingly, the shrinking rate is different depending on the sequence of the triblock prepolymers, even with the same composition, probably due to the difference in the mobility of the thermoresponsive chains in CD and the bridging chains. This result suggests that the design of the triblock prepolymers, including their sequence, is the key to fine-tuning of the properties of the gel. Thus, the appropriate design of the CD structures may contribute to achieving polymer gels with novel functions, and we are further investigating not only the swelling properties but also the mechanical properties of gels with CD structures.

Summary and outlook

From the viewpoint of synthetic chemistry, polymer gels are difficult to prepare in a precise manner due to their structural complexity and the difficulties associated with their analysis. However, since polymer gels are promising materials for various applications, the precise design of network structures should not be avoided in the development of highly functional materials through the maximization of gel characteristics. The advances in precision radical polymerization have gradually opened the door to controlling the network structure and functions of polymer gels, as discussed in this focus review. We believe that gels with complicated structures are challenging and fascinating targets for synthesis and that more synthetic chemists will study the chemistry of gels in the near future. At the same time, analytical techniques have undergone remarkable advances, and further development is expected through the cooperation among researchers in diverse fields.

References

Osada Y, Gong J. Stimuli-responsive polymer gels and their application to chemomechanical systems. Prog Polym Sci. 1993;18:187–226.

Kikuchi A, Okano T. Pulsatile drug release control using hydrogels. Adv Drug Deliv Rev. 2002;54:53–77.

Chaterji S, Kwon IK, Park K. Smart polymeric gels: redefining the limits of biomedical devices. Prog Polym Sci. 2007;32:1083–122.

Oh JK, Drumright R, Siegwart DJ, Matyjaszewski K. The development of microgels/nanogels for drug delivery applications. Prog Polym Sci. 2008;33:448–77.

Sasaki Y, Akiyoshi K. Nanogel engineering for new nanobiomaterials: from chaperoning engineering to biomedical applications. Chem Rec. 2010;10:366–76.

Diaz Diaz D, Kuhbeck D, Koopmans RJ. Stimuli-responsive gels as reaction vessels and reusable catalysts. Chem Soc Rev. 2011;40:427–48.

Caló E, Khutoryanskiy VV. Biomedical applications of hydrogels: a review of patents and commercial products. Eur Polym J. 2015;65:252–67.

Tanaka T, Fillmore D, Sun S-T, Nishio I, Swislow G, Shah A. Phase transitions in ionic gels. Phys Rev Lett. 1980;45:1636–9.

Hirokawa Y, Tanaka T. Volume phase transition in a nonionic gel. J Chem Phys. 1984;81:6379–80.

Schild HG. Poly(N-isopropylacrylamide): experiment, theory and application. Prog Polym Sci. 1992;17:163–249.

Halperin A, Kröger M, Winnik FM. Poly(N-isopropylacrylamide) phase diagrams: fifty years of research. Angew Chem Int Ed. 2015;54:15342–67.

Shibayama M. Spatial inhomogeneity and dynamic fluctuations of polymer gels. Macromol Chem Phys. 1998;199:1–30.

Di Lorenzo F, Seiffert S. Nanostructural heterogeneity in polymer networks and gels. Polym Chem. 2015;6:5515–28.

Seiffert S. Origin of nanostructural inhomogeneity in polymer-network gels. Polym Chem. 2017;8:4472–87.

Moad G, Rizzardo E, Thang SH. Living radical polymerization by the RAFT process. Aust J Chem. 2005;58:379–410.

Moad G, Rizzardo E, Thang SH. Living radical polymerization by the RAFT process—a second update. Aust J Chem. 2009;62:1402–72.

Gregory A, Stenzel MH. Complex polymer architectures via RAFT polymerization: from fundamental process to extending the scope using click chemistry and nature’s building blocks. Prog Polym Sci. 2012;37:38–105.

Ouchi M, Terashima T, Sawamoto M. Transition metal-catalyzed living radical polymerization: toward perfection in catalysis and precision polymer synthesis. Chem Rev. 2009;109:4963–5050.

Rosen BM, Percec V. Single-electron transfer and single-electron transfer degenerative chain transfer living radical polymerization. Chem Rev. 2009;109:5069–119.

Yamago S. Precision polymer synthesis by degenerative transfer controlled/living radical polymerization using organotellurium, organostibine, and organobismuthine chain-transfer agents. Chem Rev. 2009;109:5051–68.

Matyjaszewski K, Tsarevsky NV. Macromolecular engineering by atom transfer radical polymerization. J Am Chem Soc. 2014;136:6513–33.

Iha RK, Wooley KL, Nyström AM, Burke DJ, Kade MJ, Hawker CJ. Applications of orthogonal “click” chemistries in the synthesis of functional soft materials. Chem Rev. 2009;109:5620–86.

Gérard H. Model networks based on ‘endlinking’ processes: synthesis, structure and properties. Prog Polym Sci. 1998;23:1019–149.

Sakai T, Matsunaga T, Yamamoto Y, Ito C, Yoshida R, Suzuki S, et al. Design and fabrication of a high-strength hydrogel with ideally homogeneous network structure from tetrahedron-like macromonomers. Macromolecules. 2008;41:5379–84.

Li X, Tsutsui Y, Matsunaga T, Shibayama M, Chung U-i, Sakai T. Precise control and prediction of hydrogel degradation behavior. Macromolecules. 2011;44:3567–71.

Akagi Y, Gong JP, Chung U-i, Sakai T. Transition between phantom and affine network model observed in polymer gels with controlled network structure. Macromolecules. 2013;46:1035–40.

Sakai T, Akagi Y, Kondo S, Chung U. Experimental verification of fracture mechanism for polymer gels with controlled network structure. Soft Matter. 2014;10:6658–65.

Fujiyabu T, Toni F, Li X, Chung U-i, Sakai T. Three cooperative diffusion coefficients describing dynamics of polymer gels. Chem Commun. 2018;54:6784–7.

Zhou H, Johnson JA. Photo-controlled growth of telechelic polymers and end-linked polymer gels. Angew Chem Int Ed. 2013;52:2235–8.

Johnson JA, Lewis DR, Díaz DD, Finn MG, Koberstein JT, Turro NJ. Synthesis of degradable model networks via ATRP and click chemistry. J Am Chem Soc. 2006;128:6564–5.

Ooi HW, Jack KS, Whittaker AK, Peng H. Photo-initiated thiol–ene “click” hydrogels from RAFT-synthesized poly(N-isopropylacrylamide). J Polym Sci Part A: Polym Chem. 2013;51:4626–36.

Ooi HW, Jack KS, Peng H, Whittaker AK. “Click” PNIPAAm hydrogels—a comprehensive study of structure and properties. Polym Chem. 2013;4:4788–4800.

Oshima K, Fujimoto T, Minami E, Mitsukami Y. Model polyelectrolyte gels synthesized by end-linking of tetra-arm polymers with click chemistry: synthesis and mechanical properties. Macromolecules. 2014;47:7573–80.

Wang Y, Gu Y, Keeler EG, Park JV, Griffin RG, Johnson JA. Star polyMOCs with diverse structures, dynamics, and functions by three-component assembly. Angew Chem Int Ed. 2017;56:188–92.

Apostolides DE, Patrickios CS, Sakai T, Guerre M, Lopez G, Améduri B, et al. Near-model amphiphilic polymer conetworks based on four-arm stars of poly(vinylidene fluoride) and poly(ethylene glycol): synthesis and characterization. Macromolecules. 2018;51:2476–88.

Kamata H, Kushiro K, Takai M, Chung U-i, Sakai T. Non-osmotic hydrogels: a rational strategy for safely degradable hydrogels. Angew Chem Int Ed. 2016;55:9282–6.

Jochi Y, Seki T, Soejima T, Satoh K, Kamigaito M, Takeoka Y. Spontaneous synthesis of a homogeneous thermoresponsive polymer network composed of polymers with a narrow molecular weight distribution. NPG Asia Materials. 2018;10:840–8.

You Y-Z, Hong C-Y, Bai R-K, Pan C-Y, Wang J. Photo-initiated living free radical polymerization in the presence of dibenzyl trithiocarbonate. Macromol Chem Phys. 2002;203:477–83.

Ran R, Yu Y, Wan T. Photoinitiated RAFT polymerization in the presence of trithiocarbonate. J Appl Polym Sci. 2007;105:398–404.

Amamoto Y, Kamada J, Otsuka H, Takahara A, Matyjaszewski K. Repeatable photoinduced self-healing of covalently cross-linked polymers through reshuffling of trithiocarbonate units. Angew Chem Int Ed. 2011;50:1660–3.

Nicolaÿ R, Kamada J, Van Wassen A, Matyjaszewski K. Responsive gels based on a dynamic covalent trithiocarbonate cross-linker. Macromolecules. 2010;43:4355–61.

Ida S, Kimura R, Tanimoto S, Hirokawa Y. End-crosslinking of controlled telechelic poly(N-isopropylacrylamide) toward a homogeneous gel network with photo-induced self-healing. Polym J. 2017;49:237–43.

Ida S, Yamawaki M, Maruta T, Hirokawa Y. Precision synthesis of telechelic poly(N-isopropylacrylamide) with thiol-termini for construction of homogeneous network by thiol-ene end-crosslinking. Trans Mat Res Soc Jpn. 2018;43:71–74.

Willcock H, O’Reilly RK. End group removal and modification of RAFT polymers. Polym Chem. 2010;1:149–57.

Miyazaki H, Kataoka K. Preparation of polyacrylamide derivatives showing thermo-reversible coacervate formation and their potential application to two-phase separation processes. Polymer. 1996;37:681–5.

Sugihara S, Kanaoka S, Aoshima S. Thermosensitive random copolymers of hydrophilic and hydrophobic monomers obtained by living cationic copolymerization. Macromolecules. 2004;37:1711–9.

Mun GA, Nurkeeva ZS, Beissegul AB, Dubolazov AV, Urkimbaeva PI, Park K, et al. Temperature-responsive water-soluble copolymers based on 2-hydroxyethyl acrylate and butyl acrylate. Macromol Chem Phys. 2007;208:979–87.

Komatsu S, Asoh T-A, Ishihara R, Kikuchi A. Facile preparation of degradable thermoresponsive polymers as biomaterials: thermoresponsive polymers prepared by radical polymerization degrade to water-soluble oligomers. Polymer. 2017;130:68–73.

Ida S, Kawahara T, Fujita Y, Tanimoto S, Hirokawa Y. Thermoresponsive properties of copolymer gels induced by appropriate hydrophilic/hydrophobic balance of monomer combination. Macromol Symp. 2015;350:14–21.

Ida S, Kawahara T, Kawabata H, Ishikawa T, Hirokawa Y. Effect of monomer sequence along network chains on thermoresponsive properties of polymer gels. Gels. 2018;4:22.

Patrickios CS, Georgiou TK. Covalent amphiphilic polymer networks. Curr Opin Colloid Interface Sci. 2003;8:76–85.

Erdodi G, Kennedy JP. Amphiphilic conetworks: definition, synthesis, applications. Prog Polym Sci. 2006;31:1–18.

Triftaridou AI, Hadjiyannakou SC, Vamvakaki M, Patrickios CS. Synthesis, characterization, and modeling of cationic amphiphilic model hydrogels: effects of polymer composition and architecture. Macromolecules. 2002;35:2506–13.

Rikkou-Kalourkoti M, Loizou E, Porcar L, Matyjaszewski K, Patrickios CS. End-linked, amphiphilic, degradable polymer conetworks: synthesis by sequential atom transfer radical polymerization using a bifunctional, cleavable initiator. Polym Chem. 2012;3:105–16.

Kitiri EN, Patrickios CS, Voutouri C, Stylianopoulos T, Hoffmann I, Schweins R, et al. Double-networks based on pH-responsive, amphiphilic “core-first” star first polymer conetworks prepared by sequential RAFT polymerization. Polym Chem. 2017;8:245–59.

Erdodi G, Kennedy JP. Ideal tetrafunctional amphiphilic PEG/PDMS conetworks by a dual-purpose extender/crosslinker. II. Characterization and properties of water-swollen. Membr J Polym Sci Part A: Polym Chem. 2005;43:4965–71.

Fodor C, Kali G, Iván B. Poly(N-vinylimidazole)-l-poly(tetrahydrofuran) amphiphilic conetworks and gels: synthesis, characterization, thermal and swelling behavior. Macromolecules. 2011;44:4496–502.

Kali G, Iván B. Poly(methacrylic acid)-l-polyisobutylene amphiphilic conetworks by using an ethoxyethyl-protected comonomer: synthesis, protecting group removal in the cross-linked state, and characterization. Macromol Chem Phys. 2015;216:605–13.

Kaneko Y, Nakamura S, Sakai K, Aoyagi T, Kikuchi A, Sakurai Y, et al. Rapid deswelling response of poly(N-isopropylacrylamide) hydrogels by the formation of water release channels using poly(ethylene oxide) graft chains. Macromolecules. 1998;31:6099–105.

Cong H, Li L, Zheng S. Poly(N-isopropylacrylamide)-block-poly(vinyl pyrrolidone) block copolymer networks: synthesis and rapid thermoresponse of hydrogels. Polymer. 2013;54:1370–80.

Kamata H, Akagi Y, Kayasuga-Kariya Y, Chung U-i, Sakai T. “Nonswellable” hydrogel without mechanical hysteresis. Science. 2014;343:873–5.

Kamata H, Chung U, Shibayama M, Sakai T. Anomalous volume phase transition in a polymer gel with alternative hydrophilic-amphiphilic sequence. Soft Matter. 2012;8:6876–9.

Guo H, Sanson N, Hourdet D, Marcellan A. Thermoresponsive toughening with crack bifurcation in phase-separated hydrogels under isochoric conditions. Adv Mater. 2016;28:5857–64.

Guo H, Mussault C, Brûlet A, Marcellan A, Hourdet D, Sanson N. Thermoresponsive toughening in LCST-type hydrogels with opposite topology: from structure to fracture properties. Macromolecules. 2016;49:4295–306.

Ida S, Kitanaka H, Ishikawa T, Kanaoka S, Hirokawa Y. Swelling properties of thermoresponsive/hydrophilic co-networks with functional crosslinked domain structures. Polym Chem. 2018;9:1701–9.

Acknowledgements

The author is deeply grateful to Professor Yoshitsugu Hirokawa and Professor Shokyoku Kanaoka for their encouragement and support. The author also thanks the students in the laboratory. The partial supported for this research provided by the Japan Society for the Promotion of Science through a Grant-in-aid for Young Scientists (B) (No. 16K17962) is also appreciated.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ida, S. Structural design of vinyl polymer hydrogels utilizing precision radical polymerization. Polym J 51, 803–812 (2019). https://doi.org/10.1038/s41428-019-0204-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-019-0204-5