Abstract

2D material hydrogels have recently sparked tremendous interest owing to their potential in diverse applications. However, research on the emerging 2D MXene hydrogels is still in its infancy. Herein, we show a universal 4D printing technology for manufacturing MXene hydrogels with customizable geometries, which suits a family of MXenes such as Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx. The obtained MXene hydrogels offer 3D porous architectures, large specific surface areas, high electrical conductivities, and satisfying mechanical properties. Consequently, ultrahigh capacitance (3.32 F cm−2 (10 mV s−1) and 233 F g−1 (10 V s−1)) and mass loading/thickness-independent rate capabilities are achieved. The further 4D-printed Ti3C2Tx hydrogel micro-supercapacitors showcase great low-temperature tolerance (down to –20 °C) and deliver high energy and power densities up to 93 μWh cm−2 and 7 mW cm−2, respectively, surpassing most state-of-the-art devices. This work brings new insights into MXene hydrogel manufacturing and expands the range of their potential applications.

Similar content being viewed by others

Introduction

The recent boom in portable electronics, hybrid/electric vehicles, and intermittent energy (e.g., sun and wind) harvesting highlights the need for efficient energy-storage systems1,2. Supercapacitors (SCs), as promising candidates, have stuck out because of their high power density and long cycle life, which enable fast charging and eliminate the need for replacement of energy-storage devices over the lifetime of equipment that they power. However, SCs suffer from low energy density which impedes their wide implementations; one feasible approach to bypass this is developing advanced electrode materials3.

Conductive hydrogels, particularly those based on conductive 2D materials (e.g., graphene and MXene), can be used as electrode materials with high energy and power densities4,5. They not only possess large surface areas and hydrophilic properties but also maintain the high electrical conductivity of 2D materials, allowing for electrochemical reactions, fast electrolyte ion transport and electron transfer even in thick electrodes4. 2D MXenes with a formula of Mn+1XnTx (M is an early transition metal, X is carbon and/or nitrogen, n is an integer between 1 and 4, and Tx represents surface functional groups) offer a large number of promising candidates for designing conductive 2D hydrogels owing to their large surface-area-to-volume ratios, high electrical conductivities (≥20,000 S cm–1), redox capable surface groups, and chemical/structural diversities6,7,8,9,10,11. To date, several MXene hydrogels have been developed by filtration12, or using metal ions13, graphene oxide14, or polymers (e.g., polyvinyl alcohol (PVA)15, polyacrylamide16, cellulose17, chitosan18, poly(acrylic acid)19, and poly(N-isopropylacrylamide)20) as crosslinkers, and have demonstrated some success. Nevertheless, research on MXene hydrogels is still in its infancy, and serious challenges remain. First, the previous reports all focused on Ti3C2Tx; no other MXene hydrogels (beyond Ti3C2Tx) have been reported. Second, the polymer crosslinkers employed were insulating, which lowered the electrical conductivity of MXene hydrogels and weakened their electrical/electrochemical performance. Third, the geometry of these MXene hydrogels strongly depends on the shape and size of molds, which is unlikely to meet the requirements of complexity and precision in many scenarios, especially in the context of the rapid development of portable electronics.

Additive manufacturing, or 3D printing, offers an efficient approach to realizing the precise, mold-free, and low-cost fabrication of complex objects by layer-by-layer deposition of material21. With the introduction of the fourth dimension of time, 4D printing (3D printing + time) emerged22. It not only inherits all merits of 3D printing but also allows the static objects created by 3D printing to intentionally change their shape, property, or functionality over time when exposed to specific external stimuli (e.g., heat, light, water, pH)23, endowing the printed objects with new features. However, no related works on MXene hydrogels were ever reported.

Herein, an advanced 4D printing technology is developed for scalable manufacturing of MXene hydrogels, with the conducting polymer poly(3,4-ethylenedioxythiophene):poly(styrene sulfonate) (PEDOT:PSS) as the crosslinker. Differing from the dissolvable MXene sol patterns produced by traditional 3D printing (Supplementary Table 1), in our 4D printing technology, crosslinked MXene hydrogels with enhanced mechanical strengths are obtained by employing a simple heat-stimulated self-assembly process. This strategy shows remarkable universality, which allows the fabrication of a series of MXene hydrogels including Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx hydrogels. Notably, these three kinds of MXenes possess different numbers of atomic layers (n = 1, 2, and 3) and different transition metals (Nb, Ti, Mo) on their surface, representing a large family of MXenes with diverse structures and properties. In addition, the geometries of the 4D-printed MXene hydrogels are precisely customizable: various complex architectures such as microlattice, rectangular hollow prism, Chinese knot, “CRANN” logo, and micro-supercapacitor (MSC) units are easily produced. Meanwhile, they all feature excellent hydrophilic properties, large specific surface areas, and high electrical conductivities. Consequently, the Ti3C2Tx hydrogel electrodes show a large areal capacitance of 3.32 F cm−2 at 10 mV s−1, an ultrahigh specific capacitance of 232.9 F g−1 at 10 V s−1, and mass loading/thickness-independent rate capabilities. Furthermore, the 4D-printed MXene hydrogel MSCs enable low-temperature operation, with high capacitance retentions of 90.6% at 0 °C and 82.2% at –20 °C. More importantly, the energy and power densities of our MSCs reach up to 92.88 μWh cm−2 and 6.96 mW cm−2, respectively, demonstrating their potential as efficient energy-storage devices.

Results

4D printing of MXene hydrogels

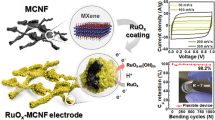

Figure 1 schematically represents the 4D printing methodology developed for manufacturing MXene hydrogels. A homogenous ink with the required rheological properties was formulated by mixing few-layer MXenes, PEDOT:PSS, and additives (dimethyl sulfoxide (DMSO), sulfuric acid (H2SO4), and sodium L-ascorbate). After 3D printing, various MXene sol patterns and architectures were obtained, which further transformed into MXene hydrogels via a heat-stimulated self-assembly process. Additives play a crucial role during the self-assembly process, as DMSO and H2SO4 simultaneously facilitate the self-assembly of MXene hydrogels, whilst sodium L-ascorbate is a reducing agent that protects MXenes from oxidation24.

The composite inks consisting of MXenes, PEDOT:PSS, and additives (DMSO, H2SO4, and sodium L-ascorbate) are 3D-printed into designed patterns first, followed by a self-assembly process, MXene sols transform into MXene hydrogels. Three kinds of MXenes, Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx, are employed for demonstration of the universality and feasibility of this technology.

Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx MXenes were synthesized by etching their precursor MAX phases in hydrochloric acid-lithium fluoride (HCl-LiF) or hydrofluoric acid (HF) solutions (see Methods). The obtained MXenes all present characteristic peaks in the X-ray diffraction patterns (Supplementary Fig. 1) and contain ultrathin 2D flakes in the transmission electron microscopy (TEM) images (Supplementary Fig. 2), demonstrating their high quality. Since the self-assembly process is crucial for the formation of MXene hydrogels from MXene sols, this was first investigated on Ti3C2Tx MXene as an example, before moving to 3D printing. As shown in Fig. 2a, pure PEDOT:PSS hydrogel shows the most distinct volume shrinkage after self-assembly at 90 °C for 6 h. With the continuous introduction of Ti3C2Tx MXene, the volume contraction of hydrogels becomes progressively less prominent. Hydrogels could not be formed from pure MXene. The maximum load of Ti3C2Tx in hydrogels is 80 wt.%, and in this case, the produced Ti3C2Tx hydrogel could be readily transferred into another glass vial without breakage (Supplementary Fig. 3a). In addition, the shapes of Ti3C2Tx hydrogels (80 wt.%) are easily customizable: cones, hemispheres, cylinders, and fibers were all produced using different molds. More interestingly, the fiber-shaped Ti3C2Tx hydrogels show great flexibility, which has been demonstrated by patterning the letters “TCD” (Supplementary Fig. 3b). Thus, in the following experiments, the mass content of MXene in hydrogels was set to 80 wt.%. Apart from the MXene mass ratio, H2SO4 and DMSO also have crucial effects on the self-assembly process (Supplementary Figs. 4 and 5). In the absence of DMSO, the Ti3C2Tx hydrogels obtained in 0.1 M H2SO4 are rigid and fragile, and in 1 M H2SO4, hydrogels cannot even form (Supplementary Fig. 4a). While in absence of H2SO4, Ti3C2Tx hydrogels are soft and easily broken (Supplementary Fig. 4b), the volume fraction of DMSO also matters (Supplementary Fig. 5). Ultimately, the optimal formula for additives was determined to be 0.1 M H2SO4 plus 26 vol.% DMSO, and the molar ratio of the reducing agent sodium L-ascorbate to the metal atom in MXene was 1:1 (see Methods).

a Photographs of Ti3C2Tx hydrogels with different MXene contents prepared by self-assembly. b Viscosity as a function of shear rate for Nb2CTx, Ti3C2Tx and Mo2Ti2C3Tx inks. c Storage modulus (G′) and loss modulus (G′′) as a function of the shear stress for Nb2CTx, Ti3C2Tx and Mo2Ti2C3Tx inks. d Frequency dependency of the ratio of the G′ to G″ for Nb2CTx, Ti3C2Tx and Mo2Ti2C3Tx inks. e Photographs of 4D-printed MXene hydrogel architectures (from left to right): Ti3C2Tx hydrogel microlattice on glass slide, Ti3C2Tx hydrogel rectangular hollow prism on glass slide, Nb2CTx hydrogel Chinese knot on cloth, Nb2CTx hydrogel “CRANN” logo on PET film, flexible Mo2Ti2C3Tx hydrogel MSC units on PET film. All scale bars in e correspond to 1 cm. f SEM and energy-dispersive X-ray spectroscopy (EDX) mapping images of Nb2CTx hydrogel. g SEM and EDX mapping images of Ti3C2Tx hydrogel. h SEM and EDX mapping images of Mo2Ti2C3Tx hydrogel. All scale bars in SEM images in f–h are 5 μm and all scale bars in EDX mapping images in f–h are 20 μm. i I−V curves of Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx hydrogels with a size of 10 × 2 × 2 mm. j Raman spectra of pure PEDOT:PSS film and 4D-printed Ti3C2Tx hydrogel. High resolution k Ti 2p and l C 1s XPS spectra of filtered Ti3C2Tx film and 4D-printed Ti3C2Tx hydrogel. Binding energies were all calibrated to the C 1s peak at 284.8 eV.

To enable 3D printing, the dispersions consisting of MXenes (Nb2CTx, Ti3C2Tx, or Mo2Ti2C3Tx), PDEOT:PSS, and additives in the above discussed proportions, were condensed by high-speed centrifugation, resulting in solid-like inks with MXene-PEDOT:PSS presenting a concentration of ~50 mg mL–1 (Supplementary Fig. 6). A rheological study was carried out to probe the suitability of these inks for 3D printing (Fig. 2b–d). As shown in Fig. 2b, the Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx inks all exhibit high apparent viscosities and shear-thinning non-Newtonian behavior, which ensures the continuous flow of inks through nozzles and the shape fidelity once the applied stress is released. Figure 2c depicts the storage modulus (G′) and loss modulus (G″) of the inks. The yield stress (crossover point between G′ and G″) values of Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx inks were measured to be 803, 664, and 778 Pa, respectively, which markedly exceed the requirement for 3D printing of MXenes (ca. 100 Pa)25,26. Below the yield stress (G′ > G″), the three inks behave as solids, and they flow under higher shear stress (G″ > G′), which allows for ink extrusion through nozzles. The frequency scan was also performed, as displayed in Supplementary Fig. 7, the three inks all possess higher G′ than G″ with G′ and G″ being frequency-independent throughout the measured frequency range. Moreover, the ink-processability-related parameter G′/G″ ratios of three inks fall within the range for MXene extrusion printing (from ca. 2.5 to 20) (Fig. 2d)27. This once again demonstrates the suitability of these inks for extrusion printing. Various MXene sol architectures were produced and are shown in Supplementary Movies 1–5. After a self-assembly process, the 3D-printed MXene sols further transformed into MXene hydrogels with great shape fidelity; a Ti3C2Tx hydrogel microlattice and a Ti3C2Tx hydrogel rectangular hollow prism on glass slides, a Nb2CTx hydrogel Chinese knot on cloth, a Nb2CTx hydrogel “CRANN” logo and flexible Mo2Ti2C3Tx hydrogel MSC units on polyethylene terephthalate (PET) films were fabricated with this technique to demonstrate its versatility and scalability (Fig. 2e, Supplementary Fig. 8). Additionally, treatment with concentrated H2SO4 boosted the mechanical properties of the 4D-printed hydrogels. Even after vigorous shaking, the treated Ti3C2Tx hydrogel microlattice and rectangular hollow prism retained their integrity without displaying breakage or deformation (Supplementary Movie 6, Supplementary Fig. 9). The enhanced mechanical strength will benefit MXene hydrogels in many applications. In contrast, the 3D-printed Ti3C2Tx sol microlattice broke into fragments after shaking (Supplementary Movie 7, Supplementary Fig. 10).

The microstructures of MXene hydrogels were examined with scanning electron microscopy (SEM). As displayed in Fig. 2f–h, the Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx hydrogels have porous structures with pore sizes ranging from less than a micrometer to several micrometers. TEM images also show the 3D framework of MXene hydrogel, and polymer chains sandwiched between MXene layers (Supplementary Fig. 11). N2 adsorption/desorption isotherms were recorded at 77 K to further investigate their Brunauer-Emmett-Teller (BET) specific surface areas (SSAs) and pore size distributions (Supplementary Fig. 12). The results confirmed the porosity of the MXene hydrogels materials, as indicated by their type II adsorption isotherms, typical of macroporous sheet-like adsorbents, but combined with hysteresis, typical of mesoporous materials (Type IV isotherms). While Mo2Ti2C3Tx and Nb2CTx hydrogels present the expected narrow hysteresis loops, the Ti3C2Tx hydrogel presents a broader hysteresis which indicates the presence of slit-shaped mesopores28. The SSAs of Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx hydrogels were calculated to be 48.7, 21.8, and 21 m2 g−1, respectively, which are comparable to other porous MXene materials29. Notably, despite the porous structure inducing the formation of finite electron transport pathways, the electrical conductivities of our MXene hydrogels still reach 37, 1548, and 231 S m−1 for Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx hydrogels, respectively (Fig. 2i). This showcases the potential of these materials for applications in sensors, bioelectronics, electromagnetic interference shielding, electrochemical energy storage, etc. (Supplementary Table 2). The conductivity difference between these hydrogels should be ascribed to the intrinsic conductivity difference of the three MXenes (Supplementary Fig. 13).

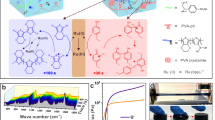

Probing self-assembly mechanism

To elucidate the self-assembly mechanism and the interactions between MXenes and PEDOT:PSS, Raman spectroscopy and X-ray photoelectron spectroscopy (XPS) were employed. In the Raman spectrum of the PEDOT:PSS film (Fig. 2j), the band at 1430 cm−1 arises from the Cα=Cβ stretching vibration of thiophene rings30, while it redshifts to 1422 cm−1 in the Ti3C2Tx hydrogel, suggesting the conformation change from benzene structure to quinoid structure and thus elongated conjugation lengths of PEDOT+ chains31. In addition, the narrower 1422 cm−1 band of the Ti3C2Tx hydrogel compared with the PEDOT:PSS film also confirms the increased crystallinity caused by the expansion and π–π stacking of the PEDOT+ chains31. In the high-resolution Ti 2p XPS spectra of Ti3C2Tx film and Ti3C2Tx hydrogel (Fig. 2k), all Ti3C2Tx hydrogel’s peaks shift to higher binding energy by about 1.0 eV, together with a slightly increased Ti−C32 contribution and somewhat decreased MXene surface groups (Supplementary Table 3). The peak corresponding to the C−Ti33 bond also shifts from 281.8 eV (Ti3C2Tx film) to 282.3 eV (Ti3C2Tx hydrogel) in the C 1s XPS spectra (Fig. 2l). Moreover, compared with Ti3C2Tx film, the C−Ti bond contribution in Ti3C2Tx hydrogel increases by three times (Supplementary Table 4), signifying the remarkably strengthened Ti−C interactions in the Ti3C2Tx hydrogel. Considerable variation also occurs in the S 2p XPS spectra, as depicted in Supplementary Fig. 14, where the ratio of PSS− to PEDOT+ in pure PEDOT:PSS film is 2.2, while this value halves in Ti3C2Tx hydrogel (1.1), a strong indication of the prominent removal of PSS− chains in Ti3C2Tx hydrogel.

Generally, PEDOT:PSS tends to form a core-shell structure with the hydrophilic PSS− shell surrounding the hydrophobic PEDOT+ core34. PEDOT+ and PSS− chains interact via electrostatic attraction, and the electrostatic repulsion between ionic PSS− chains makes PEDOT:PSS hydrophilic and dispersible in water35. This feature enables the homogeneous blending of PEDOT:PSS with MXenes. Because of the electrostatic interaction and hydrogen bonding between MXene surface groups (−O, −OH, −F) and PEDOT:PSS36, the original electrostatic interactions between PEDOT+ and PSS− are altered. Partial PEDOT+ chains attach to the negatively charged MXene surface and oxidize from benzene to quinoid configuration37. Once H2SO4 is introduced, the abundant H+ ions further protonate PSS− and weaken the electrostatic attraction between PEDOT+ and PSS− chains38, as well as the repulsion force between PEDOT:PSS micelles31. As a result, more coiled PEDOT+ chains expand to linear structures with elongated conjugation lengths, and more PSS− chains are removed from PEDOT:PSS and dissolved in the acidic solution. These exposed PEDOT+ chains not only interact with each other to form physical crosslinks through π–π stacking and hydrophobic interaction34 but also interact with MXene sheets via electrostatic attraction and hydrogen bonding and bridge them into 3D networks (Figs. 1, 2f–h and Supplementary Fig. 11). Meanwhile, the strengthened Ti–C bonds and reduced MXene surface groups are observed (Supplementary Tables 3 and 4), owing to the robust interactions between MXene and PEDOT+. Polar DMSO is a secondary dopant39 that promotes the removal of PSS− from PEDOT:PSS, like H2SO4, and they synergistically contribute to the self-assembly process (Supplementary Figs. 4 and 5). The heating treatment is indispensable during self-assembly, which accelerates these processes and strengthens the interactions, facilitating the generation of robust MXene hydrogels within a short time.

High-rate electrochemical performance of 4D-printed MXene hydrogel electrodes

To demonstrate the feasibility of 4D-printed MXene hydrogels for electrochemical energy storage, we chose Ti3C2Tx hydrogel as a model and investigated its electrochemical performance as supercapacitor electrode in Swagelok cell (Supplementary Fig. 15) (PEDOT:PSS hydrogel and Ti3C2Tx film were also tested for comparison, Supplementary Fig. 16). As shown in Fig. 3a, Ti3C2Tx hydrogel (0.5 mg cm−2) shows distinct redox peaks at approximately −0.3 V versus Ag/AgCl reference electrode at a scan rate of 10 mV s−1, and negligible distortion of cyclic voltammetry (CV) curves is observed even at 10 V s−1, indicating an ultrafast and highly reversible pseudocapacitive energy-storage process. This is also supported by the small cathodic and anodic peak potentials separation (less than 100 mV for scan rates up to 1 V s−1) (Supplementary Fig. 17). In addition, differing from the loss of pseudocapacitive characteristics in the filtered Ti3C2Tx electrode (5.0 mg cm−2) at a medium scan rate of 100 mV s−1 (Fig. 3b), redox peaks of Ti3C2Tx hydrogels remain independent of mass loading/thickness from 0.5 mg cm−2 (0.12 mm) to 6.6 mg cm−2 (1.5 mm), and are evident even in a 2.9 mm-thick hydrogel with a commercially relevant mass loading of 11.8 mg cm−2. This suggests the substantially enhanced ion-transport properties and mass loading/thickness-independent behavior of Ti3C2Tx hydrogels.

a CV curves of Ti3C2Tx hydrogel (0.5 mg cm−2) at scan rates of 10, 20, 50, 100, 200, 500, 1000, 2000, 3000, 5000, and 10,000 mV s−1. b CV curves of Ti3C2Tx hydrogels with different mass loadings at a scan rate of 100 mV s−1. c Determination of the slope, b-value, for Ti3C2Tx hydrogels with different mass loadings. d Rate performance of Ti3C2Tx hydrogels at scan rates from 10 to 10,000 mV s−1. The porous Ti3C2Tx (4.3 mg cm−2)12 and liquid-crystalline Ti3C2Tx (6.16 mg cm−2)41 are plotted for comparison. e Capacitance retentions of Ti3C2Tx hydrogels with different mass loadings at 1 V s−1. Lots of high-rate electrodes are listed for comparison, including filtered porous Ti3C2Tx43, reassembled Ti3C2Tx50, Ti3C2Tx-NbN51, graphene ribbon52, filtered Ti3C2Tx53, liquid-crystalline Ti3C2Tx41, 1T-MoS242, oxidized Ti3C2Tx54, and filtered Ti3C2Tx hydrogel12. f Areal capacitance of Ti3C2Tx hydrogels with different mass loadings at scan rates from 10 to 10,000 mV s−1. g Comparison of the areal capacitance of Ti3C2Tx hydrogels with benchmark electrodes at scan rates of 1 and 2 V s−1. These electrodes are porous Ti3C2Tx12, liquid-crystalline Ti3C2Tx41, 1 T−MoS242, filtered Ti3C2Tx hydrogel12, and filtered porous Ti3C2Tx43. h EIS plots of Ti3C2Tx hydrogels with different mass loadings taken at 0.2 V. i Long-term stability of Ti3C2Tx hydrogel performed by cycling at 100 mV s−1. The inset depicts galvanostatic charge-discharge (GCD) profiles of Ti3C2Tx hydrogel (1.0 mg cm−2) at ultrahigh current densities of 100, 200, 300, 500, and 1000 A g−1, respectively. The GCD curves of this Ti3C2Tx hydrogel at low current densities of 1, 2, 3, 5, and 10 A g−1 are shown in Supplementary Fig. 20.

To interpret the capacitive performance of Ti3C2Tx hydrogels, charge-storage kinetic analysis was carried out (Fig. 3c). The peak-current density (ip) and scan rate (v) from CV curves follow the relationship: ip = avb, where a and b are variables. b-value is an indicator of the charge-storage kinetics, which is determined from the slope of the plot of log ip versus log v40. Apparently, the b-value remains close to 1 in a wide scan-rate range from 10 to 2000 mV s−1 for Ti3C2Tx hydrogels with mass loadings up to 6.6 mg cm−2, revealing that their charge-storage kinetics is surface-controlled. The diffusion-controlled mechanism becomes prominent when the mass loading of Ti3C2Tx hydrogel reaches 11.8 mg cm−2, which should be ascribed to the long ion diffusion distance in thick electrodes.

Figure 3d shows the rate performance of Ti3C2Tx hydrogels with different mass loadings/thicknesses. It is worth noting that, at an ultrahigh scan rate of 10 V s−1, the 0.12 mm-thick hydrogel (0.5 mg cm−2) delivers a record high specific capacitance of 232.9 F g−1, retaining 82% capacitance at 10 mV s−1. For thicker and higher mass loading hydrogels (0.7 mm/3.1 mg cm−2, 1.5 mm/6.6 mg cm−2), their rate performance decays are also minor at scan rates up to 1 V s−1, superior to the previously reported 180 μm-thick porous Ti3C2Tx (4.3 mg cm−2)12 and 320 μm-thick liquid-crystalline Ti3C2Tx (6.16 mg cm−2)41. The mass loading/thickness-independent rate performance of Ti3C2Tx hydrogels is further demonstrated in Fig. 3e. At a fixed high scan rate of 1 V s−1, ultrahigh capacitance retentions of 96.3%, 92.4%, and 90.2% are achieved for Ti3C2Tx hydrogels with 0.5, 3.1, and 6.6 mg cm−2 mass loadings, respectively, pronouncedly surpassing most state-of-the-art high-rate electrodes (Supplementary Table 5).

Ti3C2Tx hydrogel electrodes also show remarkable areal capacitance. As displayed in Fig. 3f, the maximum areal capacitance of Ti3C2Tx hydrogel (11.8 mg cm−2) reaches 3.32 F cm−2 at 10 mV s−1, greater than most advanced MXene electrodes (Supplementary Table 5). Meanwhile, the areal capacitance grows linearly with mass loadings from 0.5 to 11.8 mg cm−2 at scan rates up to 100 mV s−1 (Supplementary Fig. 18). At a high scan rate of 2 V s−1, this linear relationship is still maintained within a mass loading range of 0.5–6.6 mg cm−2 (Fig. 3g), indicating fast ion diffusion and high-efficiency energy-storage in Ti3C2Tx hydrogels. In commercial applications, the typical areal capacitance of electrode is 0.6 F cm−2 (horizontal dash line in Fig. 3g)42, and to date, only the liquid-crystalline Ti3C2Tx41 and 1T-MoS242 electrodes have achieved this value at 1 V s−1. Hydrogel electrodes not only meet the commercial requirements but also possess two times higher areal capacitance than liquid-crystalline Ti3C2Tx and 1T-MoS2 electrodes at both 1 and 2 V s−1 under similar mass loadings (6.16–6.6 mg cm−2). At the maximum mass loading of 11.8 mg cm−2, the areal capacitance of our Ti3C2Tx hydrogel at 1 V s−1 retains 0.89 F cm−2, which is higher than 1T-MoS242, filtered porous Ti3C2Tx43, and filtered Ti3C2Tx hydrogel12 electrodes.

Electrochemical impedance spectroscopy (EIS) measurements were conducted to offer deeper insights into the ion transport and charge transfer behavior in MXene hydrogels. As displayed in Fig. 3h, all Ti3C2Tx hydrogel electrodes, including the 2.9 mm-thick one (11.8 mg cm−2), show low series resistances (less than 0.2 Ω cm2). However, the ion diffusion resistance (Warburg impedance) between the MXene hydrogels and filtered MXene films is quite different (Supplementary Fig. 19). Unlike the filtered Ti3C2Tx electrode with a clear 45° slope in the mid-frequency region, plots of all Ti3C2Tx hydrogels are nearly vertical at all the measured frequencies, certainly demonstrating the faster ion diffusion in hydrogel electrodes, which is vital for mass loading/thickness-independent performance. Moreover, the Ti3C2Tx hydrogel is highly stable, remaining 97.8% capacitance after cycling for 20,000 times at a scan rate of 100 mV s−1 (Fig. 3i). All these results show a potential of MXene hydrogels to enable ultrahigh charge-discharge rates and long-term cycling stability within thick electrodes with high mass loading.

Charge-storage performance of 4D-printed MSCs

To investigate the suitability of MXene hydrogels for practical energy-storage applications, a symmetric Ti3C2Tx hydrogel MSC (mass loading ~35 mg cm−2) was 4D-printed and tested in a polyvinyl alcohol-ethylene glycol-sulfuric acid (PVA-EG-H2SO4) gel electrolyte (Supplementary Fig. 21). Notably, the highly conductive Ti3C2Tx hydrogel (1548 S m−1) does not require current collector. The CV curves of the 4D-printed Ti3C2Tx hydrogel MSC at scan rates from 2 to 100 mV s−1 at room temperature (25 °C) are shown in Fig. 4a. The stable operating voltage window of this MSC reaches 0.6 V, together with a pair of redox peaks observed at around 0 V, which is an indicator of the pseudocapacitive behavior and agrees with the nonlinear GCD curves (Fig. 4b). According to the CV data, the areal capacitance of the 4D-printed Ti3C2Tx hydrogel MSC reaches 2.31 F cm−2 at a scan rate of 2 mV s−1 and retains 0.53 F cm−2 when the scan rate is increased by 50-fold (100 mV s−1) (Supplementary Fig. 22). This performance surpasses most of printed MSCs (Fig. 4c, Supplementary Table 6), such as 3D-printed Ti3C2Tx MSC (2.1 F cm−2 at 1.7 mA cm−2)26, 3D-printed graphene MSC (1.57 F cm−2 at 2 mA cm−2)44, and screen-printed Ti3C2Tx MSC (0.158 F cm−2 at 0.08 mA cm−2)45. The areal energy and power densities of the 4D-printed Ti3C2Tx hydrogel MSC are also extraordinary. As displayed in Fig. 4d, the maximum areal energy and power densities of our MSC achieve 92.88 μWh cm−2 and 6.96 mW cm−2, respectively. These values are greater than most reported MSCs (Supplementary Table 7), for instance, 3D-printed Ti3C2Tx MSCs (51.7 μWh cm−2, 4 mW cm−2)46, screen-printed Ti3C2Tx MSC (1.64 μWh cm−2, 0.778 mW cm−2)45, and direct-written graphene-CNT MSC (1.36 μWh cm−2, 0.25 mW cm−2)47. It is worth mentioning that, upon optimizing the configuration of the devices (e.g., mass loading and finger electrode gap), the electrochemical performance of our MSC could be further enhanced45.

a CV curves of 4D-printed Ti3C2Tx hydrogel MSC at scan rates of 2, 5, 10, 20, 50, and 100 mV s−1. b GCD curves of 4D-printed Ti3C2Tx hydrogel MSC at current densities of 1, 2, 3, 5, and 10 mA cm−2. c Comparison of areal capacitance of 4D-printed Ti3C2Tx hydrogel MSC with other printed MSCs. d Ragone plots of 4D-printed Ti3C2Tx hydrogel MSC and other high-performance MSCs. e CV curves of 4D-printed Ti3C2Tx hydrogel MSC at a scan rate of 10 mV s−1 at 25 °C, 0, and −20 °C. Inset is the PVA-EG-H2SO4 gel electrolyte at −20 °C, showing great transparency and flexibility. f Capacitance retention of 4D-printed Ti3C2Tx hydrogel MSC during cooling/heating cycles. g Comparison of areal capacitance of 4D-printed Ti3C2Tx hydrogel MSC (10 mV s−1) with other devices at low temperatures. h Cycling performance of 4D-printed Ti3C2Tx hydrogel MSC at a current density of 30 mA cm−1 at −20 °C, inset shows the EIS data of this MSC before and after 10,000 cycles at −20 °C. i CV curves of single 4D-printed Ti3C2Tx hydrogel MSC, four MSCs in series (4 S), four MSCs in parallel (4 P), and two in series and in parallel (2S2P), at a scan rate of 5 mV s−1. Insert shows the photograph of a 4 S tandem device powering three LED indicators, demonstrating the feasibility of our MSCs for practical applications.

Low-temperature adaptability is crucial for electrochemical energy-storage devices in practical applications, but accomplishing this goal remains challenging due to the reduced mobility of electrolyte near/below their freezing points48,49. Importantly, the PVA-EG-H2SO4 gel electrolyte we used is not frozen but shows great transparency and mechanical flexibility even at −20 °C (Fig. 4e inset), differing from the icy PVA-H2SO4 electrolyte with a white color (Supplementary Fig. 23). This can be attributed to the anti-freezing feature of EG towards water and the abundant hydrogen bonds between EG molecules and PVA chains49. More importantly, the ionic conductivity of PVA-EG-H2SO4 maintains as high as 27.5 mS cm−1 at −20 °C (Supplementary Fig. 24, Supplementary Table 8), which facilitates the rapid electrolyte ions diffusion at subzero temperatures. The highly conductive and porous Ti3C2Tx hydrogel with enhanced electrolyte accessibility also potentially alleviates the adverse effects of low temperatures. Consequently, excellent low-temperature tolerance is achieved for the 4D-printed Ti3C2Tx hydrogel MSC, retaining 90.6% capacitance at 0 °C and 82.2% capacitance at −20 °C, in comparison with that at 25 °C (Fig. 4e). These values are significantly higher than other reports (Supplementary Fig. 25). Even after cooling and heating for several cycles between −20, 0, and 25 °C, the capacitance of our MSC recovers, demonstrating its remarkable low-temperature reversibility (Fig. 4f). Moreover, at –20 °C, the areal capacitance of 4D-printed Ti3C2Tx hydrogel MSC reaches 1.42 F cm−2 (10 mV s−1), superior to most high-performance low-temperature tolerant supercapacitors ever reported (Fig. 4g) (Supplementary Table 9).

To further demonstrate the potential of 4D-printed Ti3C2Tx hydrogel MSC for practical application, particularly in cold environments, a cycling test at –20 °C was conducted. As shown in Fig. 4h, our MSC retains ~81% of initial capacitance and ~100% Coulombic efficiency after 10,000 cycles. The excellent electrochemical durability is also demonstrated by the nearly unaltered EIS curves before and after cycling (Fig. 4h insert). In addition, our MSC units can be arbitrarily connected in series and/or in parallel to meet the specific energy/power requirements in real scenarios (Fig. 4i). For instance, a four in series (4 S) tandem device can readily power three LED bulbs (Fig. 4i insert).

Discussion

We have developed an advanced 4D printing technology for the efficient fabrication of MXene hydrogels. This strategy is universal in its application to a family of MXenes with different atomic layers and transition metal types (e.g., Nb2CTx, Ti3C2Tx, and Mo2Ti2C3Tx) and a series of MXene hydrogels with complex and precise architectures on various substrates were successfully manufactured. These included a Nb2CTx hydrogel Chinese knot on cloth, a Nb2CTx hydrogel “CRANN” logo on PET film, a Ti3C2Tx hydrogel microlattice and a Ti3C2Tx hydrogel rectangular hollow prism on glass slides, and Mo2Ti2C3Tx hydrogel micro-supercapacitor units on PET film. The obtained MXene hydrogels all present 3D porous structures, large specific surface areas, and high electrical conductivities. As a result, highly efficient pseudocapacitive energy storage could be achieved, including ultrahigh capacitances, excellent mass loading/thickness-independent rate capabilities, great low-temperature tolerances, and high areal energy/power densities (92.88 μWh cm−2, 6.96 mW cm−2). This work offers new insights into the manufacture of MXene hydrogels and will advance the applications of MXenes and conductive hydrogels in electrochemical energy storage and conversion, sensors, bioelectronics, electromagnetic interference shielding, water purification, and other technologies.

Methods

Synthesis of Mo2Ti2AlC3 MAX phase

To synthesize the Mo2Ti2AlC3 MAX precursor, Mo (250 mesh, Alfa Aesar, 99.9%), Ti (325 mesh, Alfa Aesar, 99.5%), Al (325 mesh, Alfa Aesar, 99.5%), and graphite (325 mesh, Alfa Aesar, 99%) powders were used, with an atomic ratio of 2:2:1.3:2.7 (50 g total). The powder mixtures were then mixed in a 2:1 ball:powder ratio with 5 mm alumina balls, and ball milled at 60 rpm for 24 h. Afterward, high-temperature sintering reactions at 1600 °C for 4 h in a Carbolite furnace were conducted, with a heating and cooling rate of 3 °C min−1, and 200 cm3 min−1 flow of ultrahigh purity Ar (99.999%). After cooling down, the porous compact product was milled using a TiN-coated milling bit and sieved through a 400-mesh sieve, producing powders with a particle size <38 μm. The powders were then added into 9 M HCl (Sigma–Aldrich, 37%) to dissolve any residual metals or intermetallics and washed with deionized water by filtration until neutral. All experiments on this study were conducted on a single batch of MAX to eliminate any artifacts from variation between MAX synthesis batches.

Synthesis of few-layer Nb2CTx

One gram of Nb2AlC MAX (400 mesh, 98%, Jilin 11 Technology, Co. Ltd, China) was first added slowly (over 10 min) into a mixture solution consisting of 2 g of LiF (Alfa Aesar, 97%) and 20 mL of 12 M HCl and stirred at 60 °C for 96 h, yielding multilayer Nb2CTx, which was further washed with 1 M HCl and deionized water by centrifugation (Heraeus Multifuge X1 Centrifuge, Thermo Fisher Scientific, USA) at 3005 × g (4000 rpm) until the supernatant became neutral. To produce few-layer Nb2CTx, the as-synthesized multilayer Nb2CTx was dispersed in 20 mL of 5 wt. % (diluted) tetramethylammonium hydroxide (TMAOH) solution (Sigma–Aldrich, 25 wt.%) and stirred at room temperature for 12 h. Afterward, the mixture was centrifuged directly at 4696 × g (5000 rpm) for 20 min, and then washed with 40 mL of deionized water by centrifugation at 15,777 × g (12,000 rpm) to remove excess TMAOH. The obtained precipitate was redispersed in deionized water and sonicated for 1 h in an ice bath with N2 bubbling. After another centrifugation at 3005 × g (4000 rpm) for 1 h, few-layer Nb2CTx dispersion with a dark color was collected.

Synthesis of few-layer Ti3C2Tx

One gram of Ti3AlC2 MAX (400 mesh, Carbon, Ukraine) was first added slowly (over 10 min) into a mixture solution consisting of 1 g of LiF and 20 mL of 9 M HCl and stirred at 35 °C for 48 h, yielding multilayer Ti3C2Tx, which as further washed with deionized water by centrifugation at 3005 × g until the supernatant became neutral. To produce few-layer Ti3C2Tx, the as-synthesized multilayer Ti3C2Tx was redispersed in deionized water and sonicated for 1 h in an ice bath with N2 bubbling. After another centrifugation at 3005 × g for 1 h, few-layer Ti3C2Tx dispersion with a dark color was collected.

Synthesis of few-layer Mo2Ti2C3Tx

One gram of Mo2Ti2AlC3 MAX was first added slowly (over 10 min) into 20 mL of HF (Acros Organics, 48–50 wt.%) and stirred at 55 °C for 96 h, yielding multilayer Mo2Ti2C3Tx, which was further washed with deionized water by centrifugation at 3005 × g until the supernatant became neutral. To produce few-layer Mo2Ti2C3Tx, the as-synthesized multilayer Mo2Ti2C3Tx was dispersed in 20 mL of 5 wt. % TMAOH solution and stirred at 35 °C for 12 h. Afterward, the mixture was centrifuged directly at 4696 × g for 20 min, and then washed with 40 mL of deionized water by centrifugation at 15,777 × g to remove excess TMAOH. The obtained precipitate was redispersed in deionized water and sonicated for 1 h in an ice bath with N2 bubbling. After another centrifugation at 3005 × g for 1 h, few-layer Mo2Ti2C3Tx dispersion with a dark color was collected.

Preparation of MXene hydrogels by self-assembly method in molds

Typically, 3.2 mL of few-layer Ti3C2Tx MXene suspension (20 mg mL−1) and 1.52 mL of PEDOT:PSS suspension (PH 1000, CleviosTM, ~10.5 mg mL−1) were first mixed into a homogenous dispersion by stirring for 30 min and sonication for 10 min. Another mixture solution containing 2.6 mL of DMSO (Sigma–Aldrich, 99.9%, anhydrous), 0.33 mL of 3 M H2SO4 (Honeywell, 95–97%), 1.15 mL of 1 M sodium L-ascorbate (Acros Organics, 99%), and 1.2 mL of deionized water was added in dropwise and kept stirring for 30 min. Afterward, the obtained black mixture with a concentration of 8 mg mL−1 was transferred into sealed molds (e.g., glass vials and capillary tubes) with different shapes and sizes and heated at 90 °C for 6 h in oven, resulting in black Ti3C2Tx MXene hydrogels (MXene mass content: 80 wt.%). The as-prepared hydrogels were further immersed in 3 M and 18.4 M H2SO4 for 24 h to enhance their mechanical strength and washed with deionized water to remove any impurities. Notably, when optimizing the self-assembly conditions, the mass content of MXene in MXene-PEDOT:PSS mixture varied from 0, 30, 50, 70, 80, 90, to 100 wt.%, the volume proportion of DMSO to the whole dispersion (include MXene suspension, PEDOT:PSS suspension, additives and deionized water) varied from 0, 13, 26, to 50 vol.%, and the concentration of H2SO4 in the whole dispersion was set as 0.1 M or 1 M. The molar ratio of the reducing agent sodium L-ascorbate to metal atom in MXene was fixed at 1:1.

4D printing of MXene hydrogels

A black mixture dispersion of MXene (Nb2CTx, Ti3C2Tx, or Mo2Ti2C3Tx), PEDOT:PSS, and additives (0.1 M H2SO4, 26 vol.% DMSO and specific amount sodium L-ascorbate) was first condensed by centrifugation at 10,956 × g (10,000 rpm), resulting in solid-like inks with MXene-PEDOT:PSS presenting a concentration of ~50 mg mL−1. The inks were then loaded into a 5 mL syringe with a stainless-steel nozzle (0.26 mm) and being 3D-printed into different architectures via a commercial 3D printer (nano3Dprint). The printing speed was set as 1000 mm min−1. After 3D printing, the obtained MXene sols were sealed in a glass container and heated at 90 °C for 6 h in oven, to accomplish the transformation of MXene sols into MXene hydrogels. These MXene hydrogels were further immersed in 3 M and 18.4 M H2SO4 for 24 h to enhance their mechanical strength (3 M and 12 M H2SO4 employed when PET substrates were utilized to avoid their dissolution). Afterward, the obtained MXene hydrogels were immersed in deionized water and washed several times to remove any impurities. The mass contents of MXenes in three hydrogels are 80 wt.% and the solid contents of three MXene hydrogels are ~4.2 wt.%.

Preparation of low-temperature tolerant polymer gel electrolyte

2.67 mL of EG (Hach) was first mixed with 5.33 mL of deionized water, then 1 g of PVA (Aldrich, Mw 89,000–98,000, 99%, hydrolyzed) was introduced and stirred at 85 °C for 4 h until dissolved. After cooling down completely, another solution consisting of 3 g of 18.4 M H2SO4, 0.67 mL of EG, and 1.33 mL of deionized water was added in slowly, and stirred for another hour, yielding the PVA-EG-H2SO4 gel electrolyte.

Fabrication of micro-supercapacitors

4D-printed MXene hydrogel MSC (Supplementary Fig. 21, mass loading ~35 mg cm−2, size 2.2 × 1.7 × 0.4 cm (L × W × H)) were vacuum-dried (~0.5 mbar) at room temperature first, then two silver wires were connected separately to the two electrodes by conductive silver paint. After completely drying, nail polish was further coated on the top of Ag paint to protect it from potential exposure to electrolytes. Afterward, a layer of PVA-EG-H2SO4 gel electrolyte (1.8 mL) was cast, and the obtained MSCs were stored in a vacuum desiccator for 10 min to facilitate the electrolyte permeation. It is worth noting that, benefiting from the high electrical conductivity of MXene hydrogels, no extra metal current collectors were employed. The size of devices shown in Fig. 4i is 2.2 × 1.7 × 0.05 cm, and 0.22 mL of gel electrolyte was employed.

Material characterization

The morphology of MXene hydrogels was observed using SEM (Zeiss ULTRA plus) and TEM (FEI Titan 80–300, 300 kV). Surface chemical information of the samples was analyzed by an Omicron Multiprobe XPS instrument equipped with a monochromatic Al Kα X-ray source (hν = 1486.6 eV). Raman spectra were recorded with a Horiba Labram Aramis Raman spectrometer at 633 nm (grating 1800 gr/mm, 10% of laser power). XRD patterns were obtained using a powder diffractometer (Bruker D8 Discover) with Cu Kα1 radiation. The N2 adsorption/desorption measurements were performed on Quantachrome Autosorb-iQ. Before measurement, the samples (vacuum-dried at room temperature) were further vacuum-dried at 150 °C for 10 h. The rheological properties of the inks were investigated using an Anton Paar MCR 302e rheometer using a 50 mm plate-plate geometry. The upper plate was a roughened plate (PP50/S) to lessen the effects of slip and a solvent trap was used to minimize the effects of evaporation.

Electrochemical measurements

All electrochemical tests were performed on a Biologic VMP300 potentiostat. For the three-electrode test, plastic Swagelok cells (PFA-420-3) were used (Supplementary Fig. 15). MXene hydrogels on glassy carbon, overcapacitive activated carbon (YP-50, Kuraray, Japan), Ag/AgCl in 3.5 M KCl, and 3 M H2SO4 (0.5 mL) were used as working electrode, counter electrode, reference electrode, and electrolyte respectively. For the MSC device test, vacuum-dried MXene hydrogels and PVA-EG-H2SO4 were the electrode materials and gel electrolyte, respectively. The room-temperature electrochemical tests were done in ambient conditions with an average temperature of 25 °C. The low-temperature electrochemical tests were conducted in a lab fridge. EIS was measured ranging from 10 mHz to 1000 kHz under a potential amplitude of 10 mV.

Calculations for the electrochemical tests

b-value calculation: the highest current i during discharging, or the current at the highest peak, was recorded as a function of the scan rate ν in the range of 10–10,000 mV s−1. By fitting log i as a function of log ν, a linear curve was obtained with its slope as the b value.

The specific capacitance (F g−1) of a single electrode was calculated based on CV curves:

where i is the current, t is the discharging time, m is the mass of entire electrode, V is the voltage window of CV scan.

The areal capacitance (F cm−2) of a single electrode was calculated as:

where Me is the mass loading of entire electrode.

As the GCD curves of electrodes are not linear, the capacity (mAh g−1) of a single electrode, instead of capacitance, was calculated from the GCD curve as:

where i is the current, Δt is the discharging time, and m is the mass of entire electrode.

For the two-electrode device (MSC), the areal capacitance (F cm−2) was evaluated based on CV curves:

where i is the current, t is the discharging time, SMSC is the entire area of MSC (including both the electrodes and gap), VMSC is the voltage window of MSC.

The areal energy density (mWh cm−2) and average power density (mW cm−2) of MSC was calculated based on the discharge scan of GCD curves:

and

where i is the current, SMSC is the entire area of MSC (including both the electrodes and gap), tMAX is the maximum discharge time, VMSC is the voltage window of MSC, Δt is the discharging time.

Ionic conductivity (mS cm−1) of PVA-EG-H2SO4 gel electrolyte was calculated according to this formula:

where L is the thickness of electrolyte, R is the resistance of electrolyte, and S is the cross-section area of electrolyte.

Data availability

The data that support the findings of this study are available from the corresponding authors upon reasonable request. Source data are provided with this paper.

References

Huang, P. et al. On-chip and freestanding elastic carbon films for micro-supercapacitors. Science 351, 691–695 (2016).

Tian, Z. et al. Printable magnesium ion quasi-solid-state asymmetric supercapacitors for flexible solar-charging integrated units. Nat. Commun. 10, 4913 (2019).

Simon, P. & Gogotsi, Y. Perspectives for electrochemical capacitors and related devices. Nat. Mater. 19, 1151–1163 (2020).

Zhang, Y.-Z. et al. MXene hydrogels: fundamentals and applications. Chem. Soc. Rev. 49, 7229–7251 (2020).

Zhang, W., Feng, P., Chen, J., Sun, Z. & Zhao, B. Electrically conductive hydrogels for flexible energy storage systems. Prog. Polym. Sci. 88, 220–240 (2019).

VahidMohammadi, A., Rosen, J. & Gogotsi, Y. The world of two-dimensional carbides and nitrides (MXenes). Science 372, eabf1581 (2021).

Anasori, B., Lukatskaya, M. R. & Gogotsi, Y. 2D metal carbides and nitrides (MXenes) for energy storage. Nat. Rev. Mater. 2, 16098 (2017).

Wang, X. et al. Influences from solvents on charge storage in titanium carbide MXenes. Nat. Energy 4, 241–248 (2019).

Li, K. et al. 3D MXene architectures for efficient energy storage and conversion. Adv. Funct. Mater. 30, 2000842 (2020).

Mathis, T. S. et al. Modified MAX phase synthesis for environmentally stable and highly conductive Ti3C2 MXene. ACS Nano 15, 6420–6429 (2021).

Pinilla, S., Coelho, J., Li, K., Liu, J. & Nicolosi, V. Two-dimensional material inks. Nat. Rev. Mater. 7, 717–735 (2022).

Lukatskaya, M. R. et al. Ultra-high-rate pseudocapacitive energy storage in two-dimensional transition metal carbides. Nat. Energy 2, 17105 (2017).

Deng, Y. et al. Fast gelation of Ti3C2Tx MXene initiated by metal ions. Adv. Mater. 31, 1902432 (2019).

Shang, T. et al. 3D macroscopic architectures from self-assembled MXene hydrogels. Adv. Funct. Mater. 29, 1903960 (2019).

Zhang, Y.-Z. et al. MXenes stretch hydrogel sensor performance to new limits. Sci. Adv. 4, eaat0098 (2018).

Liao, H., Guo, X., Wan, P. & Yu, G. Conductive MXene nanocomposite organohydrogel for flexible, healable, low-temperature tolerant strain sensors. Adv. Funct. Mater. 29, 1904507 (2019).

Xing, C. Y. et al. Two-dimensional MXene (Ti3C2)-integrated cellulose hydrogels: toward smart three-dimensional network nanoplatforms exhibiting light-induced swelling and bimodal photothermal/chemotherapy anticancer activity. ACS Appl. Mater. Interfaces 10, 27631–27643 (2018).

Rafieerad, A. et al. Sweet-MXene hydrogel with mixed-dimensional components for biomedical applications. J. Mech. Behav. Biomed. Mater. 101, 103440 (2020).

Li, X. et al. Healable, degradable, and conductive MXene nanocomposite hydrogel for multifunctional epidermal sensors. ACS Nano 15, 7765–7773 (2021).

Xue, P. et al. Near-infrared light-driven shape-morphing of programmable anisotropic hydrogels enabled by MXene nanosheets. Angew. Chem. Int. Ed. 60, 3390–3396 (2021).

Champeau, M. et al. 4D printing of hydrogels: a review. Adv. Funct. Mater. 30, 1910606 (2020).

Spiegel, C. A. et al. 4D printing at the microscale. Adv. Funct. Mater. 30, 1907615 (2020).

Kuang, X. et al. Advances in 4D printing: materials and applications. Adv. Funct. Mater. 29, 1805290 (2019).

Zhao, X. et al. Antioxidants unlock shelf-stable Ti3C2Tx (MXene) nanosheet dispersions. Matter 1, 513–526 (2019).

Fan, Z. et al. 3D-printed Zn-ion hybrid capacitor enabled by universal divalent cation-gelated additive-free Ti3C2 MXene ink. ACS Nano 15, 3098–3107 (2021).

Yang, W. et al. 3D printing of freestanding MXene architectures for current-collector-free supercapacitors. Adv. Mater. 31, 1902725 (2019).

Akuzum, B. et al. Rheological characteristics of 2D titanium carbide (MXene) dispersions: a guide for processing MXenes. ACS Nano 12, 2685–2694 (2018).

Thommes, M. et al. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 87, 1051–1069 (2015).

Zhang, P. et al. In situ ice template approach to fabricate 3D flexible MXene film-based electrode for high performance supercapacitors. Adv. Funct. Mater. 30, 2000922 (2020).

Paulraj, I. et al. High performance of post-treated PEDOT:PSS thin films for thermoelectric power generation applications. ACS Appl. Mater. Interfaces 13, 42977–42990 (2021).

Yao, B. et al. Ultrahigh-conductivity polymer hydrogels with arbitrary structures. Adv. Mater. 29, 1700974 (2017).

Halim, J. et al. X-ray photoelectron spectroscopy of select multi-layered transition metal carbides (MXenes). Appl. Surf. Sci. 362, 406–417 (2016).

Shah, S. A. et al. Template-free 3D titanium carbide (Ti3C2Tx) MXene particles crumpled by capillary forces. Chem. Commun. 53, 400–403 (2017).

Zhang, S. M. et al. Room-temperature-formed PEDOT:PSS hydrogels enable injectable, soft, and healable organic bioelectronics. Adv. Mater. 32, 1904752 (2020).

Lu, B. Y. et al. Pure PEDOT:PSS hydrogels. Nat. Commun. 10, 1043 (2019).

Ivanko, I., Svoboda, J., Lukešová, M., Šeděnková, I. & Tomšík, E. Hydrogen bonding as a tool to control chain structure of PEDOT: electrochemical synthesis in the presence of different electrolytes. Macromolecules 53, 2464–2473 (2020).

Gund, G. S. et al. MXene/polymer hybrid materials for flexible AC-filtering electrochemical capacitors. Joule 3, 164–176 (2019).

Leaf, M. A. & Muthukumar, M. Electrostatic effect on the solution structure and dynamics of PEDOT:PSS. Macromolecules 49, 4286–4294 (2016).

Liu, J. et al. Highly conductive hydrogel polymer fibers toward promising wearable thermoelectric energy harvesting. ACS Appl. Mater. Interfaces 10, 44033–44040 (2018).

Li, K. et al. An ultrafast conducting Polymer@MXene positive electrode with high volumetric capacitance for advanced asymmetric supercapacitors. Small 16, 1906851 (2020).

Xia, Y. et al. Thickness-independent capacitance of vertically aligned liquid-crystalline MXenes. Nature 557, 409–412 (2018).

Chen, W. et al. Two-dimensional quantum-sheet films with sub-1.2 nm channels for ultrahigh-rate electrochemical capacitance. Nat. Nanotech. 17, 153–158 (2022).

Kong, J. et al. High-mass-loading porous Ti3C2Tx films for ultrahigh-rate pseudocapacitors. ACS Energy Lett. 5, 2266–2274 (2020).

Tagliaferri, S. et al. Aqueous inks of pristine graphene for 3D printed microsupercapacitors with high capacitance. ACS Nano 15, 15342–15353 (2021).

Abdolhosseinzadeh, S. et al. Turning trash into treasure: additive free MXene sediment inks for screen-printed micro-supercapacitors. Adv. Mater. 32, 2000716 (2020).

Orangi, J., Hamade, F., Davis, V. A. & Beidaghi, M. 3D printing of additive-free 2D Ti3C2Tx (MXene) ink for fabrication of micro-supercapacitors with ultra-high energy densities. ACS Nano 14, 640–650 (2020).

Wang, Y. et al. Direct graphene-carbon nanotube composite ink writing all-solid-state flexible microsupercapacitors with high areal energy density. Adv. Funct. Mater. 30, 1907284 (2020).

Gao, X. et al. Maximizing ion accessibility in MXene-knotted carbon nanotube composite electrodes for high-rate electrochemical energy storage. Nat. Commun. 11, 6160 (2020).

Rong, Q., Lei, W., Huang, J. & Liu, M. Low temperature tolerant organohydrogel electrolytes for flexible solid-state supercapacitors. Adv. Energy Mater. 8, 1801967 (2018).

Wu, Z. et al. Reassembly of MXene hydrogels into flexible films towards compact and ultrafast supercapacitors. Adv. Funct. Mater. 31, 2102874 (2021).

Wang, H. et al. Enhanced rate capability of ion-accessible Ti3C2Tx-NbN hybrid electrodes. Adv. Energy Mater. 10, 2001411 (2020).

Sheng, L. et al. Multilayer-folded graphene ribbon film with ultrahigh areal capacitance and high rate performance for compressible supercapacitors. Adv. Funct. Mater. 28, 1800597 (2018).

Li, K. et al. All-pseudocapacitive asymmetric MXene-carbon-conducting polymer supercapacitors. Nano Energy 75, 104971 (2020).

Tang, J. et al. Optimizing ion pathway in titanium carbide MXene for practical high-rate supercapacitor. Adv. Energy Mater. 11, 2003025 (2021).

Acknowledgements

We acknowledge the Advanced Microscopy Laboratory for the provision of their facilities. This research was sponsored by the European Research Council ((CoG 3D2Dprint (GA 681544) and PoC Powering_eTextiles (GA 861673)) and Science Foundation Ireland (12/RC/2278_P2 and 16/RC/3872). L.H. thanks the Irish Research Council (GOIPG/2019/2642). A.Z. thanks the Irish Research Council (GOIPD/2022/443). I.V.S. thanks the Irish Research Council (IRCLA/2019/171). M.M. thanks the Science Foundation Ireland (17/CDA/4704). MXene development at Drexel University was supported by the US National Science Foundation grant DMR-2041050. For the purpose of Open Access, the author has applied a CC BY public copyright license to any Author Accepted Manuscript version arising from this submission.

Author information

Authors and Affiliations

Contributions

K.L., Y.G., and V.N. conceived the project. K.L., J.Z., and C.E.S. synthesized the MXenes. K.L., J.Z., and Y.D. conducted the 3D printing and MXene hydrogels preparation. K.L. performed SEM, Raman, and XRD analyses. A.Z. and I.V.S. performed XPS measurements. L.H. performed TEM analysis. S.B. and M.M. performed rheology analysis. S.V. and W.S. performed BET analysis. K.L. performed electrochemical tests and data analysis. K.L. wrote the manuscript, all authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Communications thanks Dong Yang and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Peer reviewer reports are available.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Source data

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Li, K., Zhao, J., Zhussupbekova, A. et al. 4D printing of MXene hydrogels for high-efficiency pseudocapacitive energy storage. Nat Commun 13, 6884 (2022). https://doi.org/10.1038/s41467-022-34583-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41467-022-34583-0

This article is cited by

-

Flexible actuation with intrinsic sensing for ram extrusion 3D printing

The International Journal of Advanced Manufacturing Technology (2024)

-

3D-printed PEDOT:PSS for soft robotics

Nature Reviews Materials (2023)

-

3D porous rGO/MXene architecture with enhanced and customizable electrochemical performance

Journal of Materials Science (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.