Abstract

Electrostatic dielectric capacitors are essential components in advanced electronic and electrical power systems due to their ultrafast charging/discharging speed and high power density. A major challenge, however, is how to improve their energy densities to effectuate the next-generation applications that demand miniaturization and integration. Here, we report a high-entropy stabilized Bi2Ti2O7-based dielectric film that exhibits an energy density as high as 182 J cm−3 with an efficiency of 78% at an electric field of 6.35 MV cm−1. Our results reveal that regulating the atomic configurational entropy introduces favourable and stable microstructural features, including lattice distorted nano-crystalline grains and a disordered amorphous-like phase, which enhances the breakdown strength and reduces the polarization switching hysteresis, thus synergistically contributing to the energy storage performance. This high-entropy approach is expected to be widely applicable for the development of high-performance dielectrics.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data supporting the findings of this study are available within the manuscript and its Supplementary Information files. Any other relevant data are also available upon request from Y.-H.L. Source data are provided with this paper and are available at https://figshare.com/articles/dataset/SourceData/19642233.

References

Chu, B. et al. A dielectric polymer with high electric energy density and fast discharge speed. Science 313, 334–336 (2006).

Wang, G. et al. Electroceramics for high-energy density capacitors: current status and future perspectives. Chem. Rev. 121, 6124–6172 (2021).

Li, Q. et al. Flexible high-temperature dielectric materials from polymer nanocomposites. Nature 523, 576–579 (2015).

Li, J. et al. Grain-orientation-engineered multilayer ceramic capacitors for energy storage applications. Nat. Mater. 19, 999–1005 (2020).

Yang, L. et al. Perovskite lead-free dielectrics for energy storage applications. Prog. Mater. Sci. 102, 72–108 (2019).

Huang, H. & Scott, J. F. Ferroelectric Materials for Energy Applications 119–168 (Wiley, 2018).

Kim, J. et al. Ultrahigh capacitive energy density in ion-bombarded relaxor ferroelectric films. Science 369, 81–84 (2020).

Shen, B., Li, Y. & Hao, X. Multifunctional all-inorganic flexible capacitor for energy storage and electrocaloric refrigeration over a broad temperature range based on PLZT 9/65/35 thick films. ACS Appl. Mater. Interfaces 11, 34117–34127 (2019).

Peng, B. et al. Large energy storage density and high thermal stability in a highly textured (111)-oriented Pb0.8Ba0.2ZrO3 relaxor thin film with the coexistence of antiferroelectric and ferroelectric phases. ACS Appl. Mater. Interfaces 7, 13512–13517 (2015).

Cho, S. et al. Strongly enhanced dielectric and energy storage properties in lead-free perovskite titanate thin films by alloying. Nano Energy 45, 398–406 (2018).

Zhu, H. et al. Increasing energy storage capabilities of space-charge dominated ferroelectric thin films using interlayer coupling. Acta Mater. 122, 252–258 (2017).

Yang, B. et al. Bi3.25La0.75Ti3O12 thin film capacitors for energy storage applications. Appl. Phys. Lett. 11, 183903 (2017).

Pan, Z. et al. Substantially improved energy storage capability of ferroelectric thin films for application in high-temperature capacitors. J. Mater. Chem. A 9, 9281–9290 (2021).

Pan, H. et al. Ultrahigh energy storage in superparaelectric relaxor ferroelectrics. Science 374, 100–104 (2021).

Pan, H. et al. Ultrahigh–energy density lead-free dielectric films via polymorphic nanodomain design. Science 365, 578–582 (2019).

Li, Y. et al. Ultrahigh-energy storage properties of (PbCa)ZrO3 antiferroelectric thin films via constructing a pyrochlore nanocrystalline structure. ACS Nano 14, 6857–6865 (2020).

Sun, Z. et al. Ultrahigh energy storage performance of lead-free oxide multilayer film capacitors via interface engineering. Adv. Mater. 29, 1604427 (2017).

Brown, E. et al. Controlling dielectric and relaxor-ferroelectric properties for energy storage by tuning Pb0.92La0.08Zr0.52Ti0.48O3 film thickness. ACS Appl. Mater. Interfaces 6, 22417–22422 (2014).

Wang, K. et al. Superparaelectric (Ba0.95,Sr0.05)(Zr0.2,Ti0.8)O3 ultracapacitors. Adv. Energy Mater. 10, 2001778 (2020).

Jiang, B. et al. High-entropy-stabilized chalcogenides with high thermoelectric performance. Science 371, 830–834 (2021).

Wang, Q. et al. Multi-anionic and -cationic compounds: new high entropy materials for advanced Li-ion batteries. Energy Environ. Sci. 12, 2433–2442 (2019).

Loffler, T. et al. Discovery of a multinary noble metal-free oxygen reduction catalyst. Adv. Energy Mater. 8, 1802269 (2018).

Sarkar, A. et al. High-entropy oxides: fundamental aspects and electrochemical properties. Adv. Mater. 31, 1806236 (2019).

Oses, C., Toher, C. & Curtarolo, S. High-entropy ceramics. Nat. Rev. Mater. 5, 295–309 (2020).

Rost, C. M. et al. Entropy-stabilized oxides. Nat. Commun. 6, 8485 (2015).

Berardan, D., Franger, S., Dragoe, D., Meena, A. K. & Dragoe, N. Colossal dielectric constant in high entropy oxides. Phys. Status Solidi RRL 10, 328–333 (2016).

Xiong, W. et al. Low-loss high entropy relaxor-like ferroelectrics with A-site disorder. J. Eur. Ceram. Soc. 41, 2979–2985 (2021).

Zhang, M. et al. Multi elements substituted aurivillius phase relaxor ferroelectrics using high entropy design concept. Mater. Des. 200, 109447 (2021).

Liu, J., Ren, K., Ma, C., Du, H. & Wang, Y. Dielectric and energy storage properties of flash-sintered high-entropy (Bi0.2Na0.2K0.2Ba0.2Ca0.2)TiO3 ceramic. Ceram. Int. 46, 20576–20581 (2020).

Yang, W. & Zheng, G. High energy-storage density and efficiency in nanostructured (Bi0.2Na0.2K0.2La0.2Sr0.2)TiO3 high-entropy ceramics. J. Am. Ceram. Soc. 105, 1083–1094 (2021).

Chon, U., Yi, G.-C. & Jang, H. M. Fatigue-free behavior of highly oriented Bi3.25La0.75Ti3O12 thin films grown on Pt/Ti/SiO2/Si (100) by metalorganic solution decomposition. Appl. Phys. Lett. 78, 658–660 (2001).

Esquivel-Elizondo, J. R., Hinojosa, B. B. & Nino, J. C. Bi2Ti2O7: it is not what you have read. Chem. Mater. 23, 4965–4974 (2011).

Kargin, Y. F., Ivicheva, S. N. & Volkov, V. V. Phase relations in the Bi2O3-TiO2 system. Russ. J. Inorg. Chem. 60, 619–625 (2015).

Dragoe, N. & Berardan, D. Order emerging from disorder. Science 366, 573–574 (2019).

Santos, V. B., M’Peko, J.-C., Mir, M., Mastelaro, V. R. & Hernandes, A. C. Microstructural, structural and electrical properties of La3+-modified Bi4Ti3O12 ferroelectric ceramics. J. Eur. Ceram. Soc. 29, 751–756 (2009).

Zhao, Y. et al. Achieving an ultra-high capacitive energy density in ferroelectric films consisting of superfine columnar nanograins. Energy Storage Mater. 39, 81–88 (2021).

Michael, E. K. & Trolier-McKinstry, S. Cubic pyrochlore bismuth zinc niobate thin films for high-temperature dielectric energy storage. J. Am. Ceram. Soc. 98, 1223–1229 (2015).

Xie, J. et al. Achieving ultrahigh energy storage performance in bismuth magnesium titanate film capacitors via amorphous-structure engineering. J. Mater. Chem. C 7, 13632–13639 (2019).

Chen, X. et al. Direct observation of chemical short-range order in a medium-entropy alloy. Nature 592, 712–716 (2021).

Zhao, Z., Xiang, H., Dai, F.-Z., Peng, Z. & Zhou, Y. (La0.2Ce0.2Nd0.2Sm0.2Eu0.2)2Zr2O7: a novel high-entropy ceramic with low thermal conductivity and sluggish grain growth rate. J. Mater. Sci. Technol. 35, 2647–2651 (2019).

Tsai, K.-Y., Tsai, M.-H. & Yeh, J.-W. Sluggish diffusion in Co-Cr-Fe-Mn-Ni high-entropy alloys. Acta Mater. 61, 4887–4897 (2013).

Gao, M. C., Yeh, J.-W., Liaw, P. K. & Zhang, Y. (eds) High-Entropy Alloys: Fundamentals and Applications 238–240 (Springer, 2016).

Mu, S. et al. Uncovering electron scattering mechanisms in NiFeCoCrMn derived concentrated solid solution and high entropy alloys. npj Comput. Mater. 5, 1 (2019).

Waser, R. & Hagenbeck, R. Grain boundaries in dielectric and mixed conducting ceramics. Acta Mater. 48, 797–825 (2000).

Li, D. et al. Enhanced energy storage properties achieved in Na0.5Bi0.5TiO3-based ceramics via composition design and domain engineering. Chem. Eng. J. 419, 129601 (2021).

Nasyrov, K. A. & Gritsenko, V. A. Transport mechanisms of electrons and holes in dielectric films. Phys. Uspekhi 183, 1099–1114 (2013).

Zhang, Y. et al. Ultrahigh energy storage and electrocaloric performance achieved in SrTiO3 amorphous thin films via polar cluster engineering. J. Mater. Chem. A 7, 17797–17805 (2019).

Chen, X. et al. Giant energy storage density in lead-free dielectric thin films deposited on Si wafers with an artificial dead-layer. Nano Energy 78, 105390 (2020).

Yang, C. et al. Fatigue-free and bending-endurable flexible Mn-doped Na0.5Bi0.5TiO3-BaTiO3-BiFeO3 film capacitor with an ultrahigh energy storage performance. Adv. Energy Mater. 9, 1803949 (2019).

Zhang, T. et al. High-energy storage density and excellent temperature stability in antiferroelectric/ferroelectric bilayer thin films. J. Am. Ceram. Soc. 100, 3080–3087 (2017).

Hao, X., Wang, Y., Zhang, L., Zhang, L. & An, S. Composition-dependent dielectric and energy-storage properties of (Pb,La)(Zr,Sn,Ti)O3 antiferroelectric thick films. Appl. Phys. Lett. 102, 163903 (2013).

Hu, Z., Ma, B., Koritala, R. E. & Balachandran, U. Temperature-dependent energy storage properties of antiferroelectric Pb0.96La0.04Zr0.98Ti0.02O3 thin films. Appl. Phys. Lett. 104, 263902 (2014).

Xie, Z. et al. Large enhancement of the recoverable energy storage density and piezoelectric response in relaxor-ferroelectric capacitors by utilizing the seeding layers engineering. Appl. Phys. Lett. 106, 202901 (2015).

Pan, H. et al. Giant energy density and high efficiency achieved in bismuth ferrite-based film capacitors via domain engineering. Nat. Commun. 9, 1813 (2018).

Wang, J. et al. Bi(Mg0.5Ti0.5)O3 addition induced high recoverable energy-storage density and excellent electrical properties in lead-free Na0.5Bi0.5TiO3-based thick films. J. Eur. Ceram. Soc. 39, 255–263 (2019).

Zhang, Y., Yu, R. & Zhu, J. Displacement separation analysis from atomic-resolution images. Ultramicroscopy 232, 113404 (2022).

Acknowledgements

We thank W. Miao for fruitful discussions. L.-Q.C. acknowledges the generous support by the Hamer Foundation through a Hamer Professorship at Penn State. Y.-H.L. was supported by the National Key Research Program of China (grant no. 2021YFB3800601). Y.-H.L., C.-W.N. and J.Z. were supported by the Basic Science Center Project of the National Natural Science Foundation of China (NSFC; grant no. 51788104). J.Z. was supported by the NSFC (grant no. 11834009), Applied Basic Research Major Programme of Guangdong Province, China (grant no. 2021B0301030003) and Jihua Laboratory (project no. X210141TL210). Q.Z. and L.G. were supported by the NSFC (grant nos 52025025 and 52072400). Z.S. was supported by the NSFC (no. 52002300) and the Major Research Plan of the NSFC (grant no. 92066103). H.H. was supported by the NSFC (grant no. 51972028). J.H. was supported by the NSFC (grant no. 11934007).

Author information

Authors and Affiliations

Contributions

Y.-H.L. and B.Y. conceived this study. B.Y. performed this study with the supervision of Y.-H.L. and C.-W.N.; B.Y., S.L. and Y.L. fabricated the samples and carried out the electrical measurements. J.Z., Y.Z., W.S., F.M., Q.Z., L.G., Y.Y. and J.H. conducted the microstructural STEM research. Z.S., H.H. and L.-Q.C. performed the phase-field simulations. B.Y., Y.Z., H.P., S.Z., L.-Q.C., J.Z., C.-W.N. and Y.-H.L. wrote the manuscript. All authors discussed the results and revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Nature Materials thanks Ben Breitung, Brahim Dkhil and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data

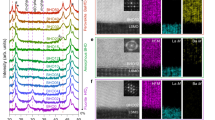

Extended Data Fig. 1 HAADF, NBD, FFT images and schematic lattice structure of the film with x = 0.4.

a, Along the [112] zone axes. b, Along the [110] zone axes.

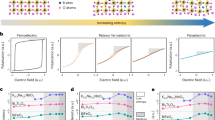

Extended Data Fig. 2 Room-temperature polarization and dielectric properties for all films.

a, Comparison of the Pm/Pr and Uloss of these films. b, Frequency dependent dielectric permittivity and loss tangent.

Extended Data Fig. 3 Bipolar P-E loops of the films at electric fields up to their breakdown field at 10 kHz.

a, x = 0.0. b, x = 0.1. c, x = 0.2. d, x = 0.3. e, x = 0.4. f, x = 0.5.

Extended Data Fig. 4 Energy storage performances for the films of x = 0.1 and 0.3.

a, Discharged energy storage density and b, energy efficiency as functions of the electric field.

Extended Data Fig. 5 Determining the center of atomic column with 2D gaussian fitting.

a, Schematic graph shows the process of determining the center of atomic column, which is not influenced by the size and contrast of atomic column. b, The raw and reference image used for measuring atomic displacement in this work. The green parallelogram represents the area exerted for determining center of atomic column and corresponding fitting results are shown below.

Extended Data Fig. 6 Displacement separated analysis.

a, The HAADF images acquired along the [110] zone axis of the x = 0.4 film. The real atom position is determined by fitting the intensity peak of the atom. b, FFT result shows the frequency information in the reciprocal space. The frequency containing non-distorted lattice is marked by a green mask, which is used for subsequent iFFT operation. c, The iFFT result of the frequency selected by masks shown in (b). Gaussian fitting is used again to determine the non-distorted atomic position. Ion displacement is calculated as the difference between the ion positions in the real and non-distorted lattices.

Supplementary information

Supplementary Information

Supplementary Figs. 1–11, Table 1, Methods and references.

Source data

Source Data Fig. 1

X-ray diffraction source data.

Source Data Fig. 2

Dielectric, leakage and breakdown source data.

Source Data Fig. 3

Grain size and amorphous-like phase source data.

Source Data Fig. 4

Energy storage source data.

Source Data Extended Data Fig. 1

Polarization and dielectric property source data.

Source Data Extended Data Fig. 2

Bipolar P–E loop source data.

Source Data Extended Data Fig. 3

Energy storage source data.

Rights and permissions

About this article

Cite this article

Yang, B., Zhang, Y., Pan, H. et al. High-entropy enhanced capacitive energy storage. Nat. Mater. 21, 1074–1080 (2022). https://doi.org/10.1038/s41563-022-01274-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41563-022-01274-6

This article is cited by

-

Multiscale reconfiguration induced highly saturated poling in lead-free piezoceramics for giant energy conversion

Nature Communications (2024)

-

High-entropy materials for energy and electronic applications

Nature Reviews Materials (2024)

-

The ultra-high electric breakdown strength and superior energy storage properties of (Bi0.2Na0.2K0.2La0.2Sr0.2)TiO3 high-entropy ferroelectric thin films

Journal of Materials Science: Materials in Electronics (2024)

-

Suppressing strain propagation in ultrahigh-Ni cathodes during fast charging via epitaxial entropy-assisted coating

Nature Energy (2024)

-

Engineering relaxors by entropy for high energy storage performance

Nature Energy (2023)